SOLUTION

JIEHUANGMIM moldingtxo lub sij hawm siv machining thaum ua tau yooj yim mus rau complex hlau qhov chaw sai sai.MIM molding qhov chaw yog cov kev xaiv zoo heev rau daim ntawv thov hauv ntau yam kev lag luam, suav nrog aerospace, tsheb, khoom siv, khoos phis tawj, kho mob, kho hniav, thiab cov khoom siv orthodontic. Ua qhov tseem ceeb nrog qhov hnyav ntawm tsawg dua 100 grams thiab qhov loj yog feem ntau 0.5 ~ 20μm yog zoo meej rau MIM (mim hlau txhaj tshuaj molding), TiMIM molding (molding titanium) thiab ceramic hmoov txhaj molding. JIEHUANG Hlau Khoom tam sim no muab ceev-tig 3D luam tawm qauv MIM-zoo li qhov chaw los txhawb cov neeg siv khoom 'R & D teg num.

MIM hlau txhaj tshuaj molding khoom

Rau qhovmim hlau txhaj molding txheej txheem, ntau yam ntawm cov hlau alloys siv tau, Nws yog tsuas yog siv rau kev tsim khoom thiab ua cov txheej txheem thiab kho kom zoo nkauj precision mechanical qhov chaw uas suav nrog ntau yam Stainless hlau, titanium, thiab Zirconia (ceramic txhaj), hais ob peb. JIEHUANG MIM yog tus kws tshaj lij hauv:

1.Cov khoom siv no suav nrog austenitic stainless hlau cov ntaub ntawv, xws li 316L, 304 series, thiab lwm yam.

2.precipitation hardening stainless hlau series xws li 17-4PH, SUS631 thiab lwm yam siab zog stainless hlau txhaj cov ntaub ntawv;

3.SUS440 series martensitic qauv stainless hlau txhaj tshuaj cov ntaub ntawv, yog dav siv nyob rau hauv instrumentation, khoom kho mob, saib kho vajtse thiab lwm yam teb.

Hais txog cov khoom ntawm koj cov khoom hlau, peb yuav muab tswv yim rau koj raws li kev siv cov khoom siv hlau.

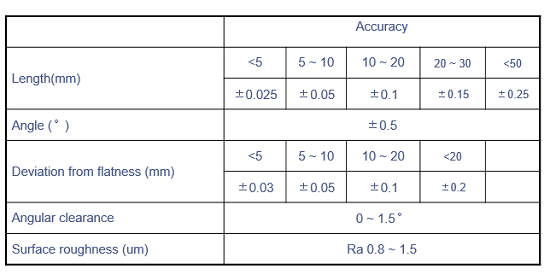

Hlau Txhaj Molding Tolerance Chart

Koj puas tsis paub meej txog qhov loj me rau MIM molding koj qhov? Xyuas kom tseeb tias txhua yam txheej txheem uas koj xaiv thaum xaiv ibhlau txhaj molding tuam txhab xa cov khoom zoo ib yam zoo thiab rov ua dua. Peb cov txheej txheem cuab yeej ib txwm yog tsim los ua kom koj cov khoom ua tau zoo thiab txo koj cov nqi.

Thov hu rau peb!

Hlau txhaj tshuaj molding txheej txheem

Kauj ruam1:Binder - lub hauv paus ntawm cov txheej txheem hlau txhaj tshuaj molding. Hauvstainless hlau txhaj molding, lub binder muaj ob txoj haujlwm tseem ceeb tshaj plaws ntawm kev txhim kho fluidity rau kev txhaj tshuaj molding thiab tswj cov duab ntawm lub compact.

Kauj ruam2:Fedstock - Kev sib xyaw ua ke yog cov txheej txheem ntawm kev sib xyaw cov hmoov hlau nrog cov binder kom tau txais cov khoom noj sib xws. Txij li qhov xwm ntawm cov khoom noj khoom noj txiav txim siab cov khoom ntawm qhov kawgtxhaj tshuaj molded khoom , cov txheej txheem no tseem ceeb heev. Qhov no suav nrog ntau yam xws li txoj hauv kev thiab kev sib txawv ntawm kev sib ntxiv ntawm cov ntawv khi thiab cov hmoov, qhov sib tov kub, thiab cov yam ntxwv ntawm cov khoom sib xyaw.

Kauj ruam3:Moulding- Lub feedstock yog rhuab thiab txhaj nyob rau hauv siab siab mus rau hauv lub pwm kab noj hniav, enabling lub creation ntawm incredibly intricate qauv. Cov tivthaiv yog hu ua "ib qho ntsuab" thaum nws tau raug tshem tawm.

Kauj ruam 4:Debinding- Tom qab "ntsuab tivthaiv" tau dhau los ua tus txheej txheem tswj kom tshem tawm cov ntawv khi, tam sim no tau npaj rau theem tom ntej. Cov tivthaiv yog hu ua "xim av" thaum cov txheej txheem debinding tiav.

Kauj ruam 5:Sintering- yog cov kauj ruam kawg hauv MIM txheej txheem, sintering tshem tawm cov pores ntawm "xim av" cov hmoov hmoov. Ua cov tshuaj MIM ncav cuag tag nrho cov kev ua tiav lossis ze rau tag nrho cov kev ua tiav.sintering txheej txheem hauv hmoov metallurgytseem ceeb heev.

Kauj ruam6: Tus qauvhmoov metallurgy txoj kev yog hlau txhaj molding. Kev kho tom qab sintering (precision pressing, dov, extrusion, quenching, nto quenching, roj immersion, thiab lwm yam) yog tsim nyog rau workpieces nrog high precision yuav tsum, siab hardness, thiab siab hnav tsis kam.

Lub workpiece yuav txawv me ntsis thaum lub sijhawm ua haujlwm tom qab thiab yuav tsum tau hloov kho dua tshiab.Cov cuab yeej shaping uas twb muaj lawm yog tus qauv tsim yooj yim thiab tuaj yeem ua cov txheej txheem thiab tsim ib qho haujlwm ntawm ib lub sijhawm, uas ua rau kev ua haujlwm qis thiab cov nqi khoom siab. Tsis tas li ntawd, lub shaping tooling tsuas yog siv rau workpieces mus txog qhov loj me; Yog hais tias qhov luaj li cas ntawm lub workpiece yuav zoo li tus loj dua qhov no, nws yuav siv tsis tau. Tom qab tus nqi, cov cuab yeej yuav tsum tau hloov, uas ua rau kev ua haujlwm qis dua.

Kauj ruam 7: Automated detection + Manual inspection of products MIM PRODUCT

Daim ntawv ceeb toom:

tom qab Sintering TAM SIM NO

Tom qabsintering, ntxiv kev ua haujlwm theem nrab

JIEHUANG muab ntau cov txheej txheem thib ob txhawm rau txhim kho qhov kev tswj xyuas qhov ntev tom qab koj cov khoom tsis muaj tag nrho cov khoom siv khi, suav nrog:

Tshuab dhos

kev npaj nto

Cov khoom yuav cuam tshuam thiab pib poob lossis luag thaum lub sijhawm sintering. Cov txheej txheem tau hais los saum toj no kho cov teeb meem no thiab coj qhov rov qab mus rau nws qhov qub tsim.