THANDIZO

JIEHUANGKupanga kwa MIMamachepetsa makina owononga nthawi pamene akupanga zitsulo zosavuta kapena zovuta kwambiri mwamsanga.Zithunzi za MIM ndi zosankha zabwino kwambiri zogwiritsira ntchito m'mafakitale osiyanasiyana, kuphatikiza zakuthambo, magalimoto, zida zamagetsi, makompyuta, zamankhwala, zamano, ndi zida za orthodontic. Kupanga magawo ofunikira okhala ndi zolemetsa zosakwana magalamu 100 ndipo kukula kwake nthawi zambiri kumakhala 0.5 ~ 20μm ndikwabwino kwa MIM(mim jekeseni wachitsulo) , TiMIM kuumba (kuumba titaniyamu) ndi jekeseni wa ufa wa ceramic. JIEHUANG Metal Products tsopano imapereka magawo osinthika a 3D osindikizidwa ngati MIM kuti athandizire zoyeserera zamakasitomala za R&D.

MIM zitsulo jekeseni akamaumba Zida

Za kumim zitsulo jekeseni akamaumba ndondomeko, lalikulu osiyanasiyana zitsulo aloyi ndi Kufikika, Iwo makamaka ntchito kupanga ndi processing wa structural ndi kukongoletsa mwatsatanetsatane mbali makina makina kuphatikizapo mitundu yosiyanasiyana ya Stainless zitsulo, titaniyamu, ndi Zirconia(ceramic jakisoni), kutchula ochepa. JIEHUANG MIM ndi katswiri mu:

1.Zinthu zamtundu uwu zimaphatikizapo zida zachitsulo zosapanga dzimbiri za austenitic, monga 316L, mndandanda wa 304, etc.,

2.precipitation kuumitsa zitsulo zosapanga dzimbiri monga 17-4PH, SUS631 ndi zina mkulu Mphamvu zosapanga dzimbiri jekeseni zipangizo;

3.SUS440 mndandanda martensitic kapangidwe zitsulo zosapanga dzimbiri jekeseni zipangizo, chimagwiritsidwa ntchito zida, zipangizo zachipatala, mawotchi hardware ndi madera ena.

Ponena za zinthu zazitsulo zanu, tidzakupatsani upangiri waukadaulo malinga ndi kugwiritsa ntchito zitsulo.

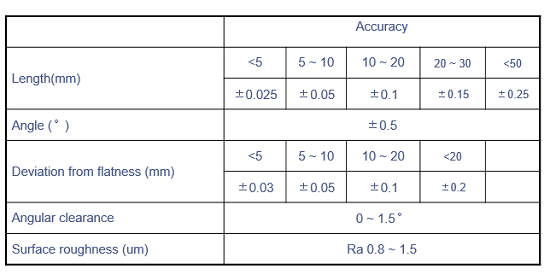

Tchati chololera jekeseni wachitsulo

Kodi simukutsimikiza kukula koyenera kwa MIM kuumba gawo lanu? Onetsetsani kuti chilichonse tooling ndondomeko kusankha posankha akampani yopanga jekeseni wazitsulo imapereka zigawo zofananira bwino komanso mobwerezabwereza. Njira zathu zopangira zida zachikhalidwe zimapangidwira kuti muwonjezere luso lanu lopanga ndikuchepetsa mtengo wanu.

Chonde titumizireni!

Metal jakisoni akamaumba ndondomeko

Khwerero1:Binder - pachimake zitsulo jekeseni akamaumba ndondomeko. Muzitsulo zosapanga dzimbiri jekeseni akamaumba, chomangiracho chili ndi ntchito ziwiri zofunika kwambiri zowonjezeretsa madzi opangira jekeseni ndikusunga mawonekedwe a compact.

Khwerero2:Feedstock - Kuphatikizira ndi njira yosakaniza ufa wachitsulo ndi chomangira kuti mupeze chakudya chofanana. Popeza chikhalidwe cha chakudya chakuthupi chimatsimikizira katundu wa chomalizamankhwala opangidwa ndi jekeseni , ndondomekoyi sitepe ndi yofunika kwambiri. Izi zimaphatikizapo zinthu zosiyanasiyana monga njira ndi kutsatizana kwa kuwonjezera kwa binder ndi ufa, kutentha kosakaniza, ndi makhalidwe a chipangizo chosakaniza.

Khwerero3:Kuumba- Chodyeracho chimatenthedwa ndikubayidwa pansi pa kupanikizika kwambiri mu nkhungu, zomwe zimapangitsa kuti pakhale zinthu zovuta kwambiri. Gawoli limatchedwa "gawo lobiriwira" likachotsedwa.

Gawo 4:Debinding- Pambuyo pa "gawo lobiriwira" lakhala ndi ndondomeko yoyendetsedwa kuti muchotse binder, tsopano yakonzekera gawo lotsatira. Chigawocho chimatchedwa "bulauni" pamene ndondomeko yomaliza itatha.

Gawo 5:Sintering- ndi sitepe yotsiriza mu ndondomeko MIM, sintering kumatha pores pakati "bulauni" mbali ufa particles. Pangani zinthu za MIM zifike pakuchulukira kwathunthu kapena kuyandikira kulimba kwathunthu.Sintering process mu powder metallurgyndizofunikira kwambiri.

Khwerero6: Zodziwikanjira ya powder metallurgy ndi jekeseni wachitsulo. Chithandizo cha post-sintering (kukankhira mwatsatanetsatane, kugudubuza, kutulutsa, kuzimitsa, kuzimitsa pamwamba, kumiza mafuta, ndi zina zotero) ndizofunikira pazitsulo zogwirira ntchito zomwe zimakhala ndi zofunikira kwambiri, kuuma kwakukulu, ndi kukana kuvala kwambiri.

Chogwiritsiridwa ntchitocho chidzasokonezedwa pang'onopang'ono panthawi yokonzanso ndipo chidzafunika kukonzanso.Chida chojambula chomwe chilipo ndi chophweka ndipo chingathe kupanga ndi kupanga ntchito imodzi panthawi imodzi, zomwe zimapangitsa kuti ntchito ikhale yochepa komanso ndalama zambiri zamtengo wapatali. Komanso, mawonekedwe tooling angagwiritsidwe ntchito workpieces mpaka kukula kwake; ngati kukula kwa workpiece kuti kuumbike ndi yaikulu kuposa osiyanasiyana, izo sizingagwiritsidwe ntchito. Pambuyo pa mtengo, zida ziyenera kusinthidwa, zomwe zimachepetsanso kugwira ntchito bwino.

Gawo 7: Kudziwikiratu + Kuwunika pamanja kwazinthu za MIM PRODUCT

Zindikirani:

pambuyo Sintering MAY BE

Pambuyokuimba, ntchito zina zachiwiri

JIEHUANG imapereka njira zingapo zachiwiri kuti ziwongolere kuwongolera zinthu zitakhala zopanda zida zonse zomangira, kuphatikiza:

Machining

Kukonzekera pamwamba

Zigawo zitha kupotoza ndikuyamba kutsika kapena kukoka panthawi yomwe sintering. Njira zomwe tazitchula pamwambazi zimakonza mavutowa ndikubweretsa gawolo ku mapangidwe ake oyambirira.