ISIXAZULULO

I-JIEHUANGUkwakhiwa kwe-MIMkunciphisa imishini edla isikhathi ngenkathi ikhiqiza izingxenye zensimbi ezilula kuya kweziyinkimbinkimbi ngokushesha.Izingxenye zokubumba ze-MIM yizinqumo ezinhle kakhulu zokusetshenziswa ezimbonini ezahlukahlukene, okuhlanganisa i-aerospace, ezezimoto, izinto zikagesi, amakhompyutha, ezokwelashwa, ezamazinyo, nemishini yamazinyo. Ukukhiqiza izingxenye ezibalulekile ezinesisindo esijwayelekile esingaphansi kwamagremu ayi-100 futhi usayizi ngokuvamile u-0.5~20μm ulungele i-MIM(mim yokubumba umjovo wensimbi), ukubumba kwe-TiMIM (i-titanium yokubumba) kanye nokubumba komjovo we-ceramic powder. I-JIEHUANG Metal Products manje inikeza izingxenye eziphrintiwe ze-3D ezifana ne-MIM ezishintsha ngokushesha ukuze zisekele imizamo ye-R&D yamakhasimende.

Izinto zokubumba umjovo wensimbi we-MIM

Okwemim ukubumba umjovo wensimbi inqubo, uhla olukhulu lwama-alloys ensimbi luyafinyeleleka, Isetshenziselwa ikakhulukazi ukukhiqiza nokucubungula izingxenye zemishini ezinembayo nezakhiwo ezihlanganisa izinhlobo ezahlukene zensimbi engagqwali, titanium, kanye neZirconia(umjovo weceramic), ukusho ezimbalwa. U-JIEHUANG MIM uchwepheshe:

1.Lolu hlobo lwempahla luhlanganisa i-austenitic stainless steel materials, njenge-316L, 304 series, njll.,

I-2.precipitation iqinisa uchungechunge lwensimbi engagqwali efana ne-17-4PH, SUS631 nezinye izinto zokujova zensimbi engenasici Amandla aphezulu;

I-3.SUS440 uchungechunge lwesakhiwo se-martensitic umjovo wensimbi engagqwali izinto, zisetshenziswa kakhulu ku-instrumentation, okokusebenza kwezokwelapha, i-hardware yewashi neminye imikhakha.

Ngokuphathelene nempahla yezingxenye zakho zensimbi, sizokunikeza iseluleko sochwepheshe ngokuvumelana nokusetshenziswa kwemikhiqizo yensimbi.

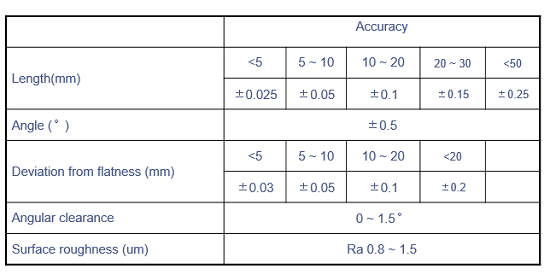

Ishadi Lokubekezelela Umjovo Wensimbi

Awunasiqiniseko ngosayizi ofanele we-MIM ekubumbeni ingxenye yakho? Qiniseka ukuthi noma iyiphi inqubo yamathuluzi oyikhethayo lapho ukhetha ainkampani yokubumba umjovo wensimbi iletha izingxenye ezingaguquki ngempumelelo nangokuphindaphindiwe. Inqubo yethu yamathuluzi evamile yenzelwe ukwandisa ukusebenza kahle kwakho kokukhiqiza nokunciphisa izindleko zakho.

Sicela usithinte!

Inqubo yokubumba umjovo wensimbi

Isinyathelo1:Isibopho - umnyombo wenqubo yokubumba umjovo wensimbi. Kuinsimbi engagqwali umjovo ekubumbeni, isibophezelo sinemisebenzi emibili eyisisekelo kakhulu yokuthuthukisa uketshezi ekubunjweni komjovo kanye nokugcina ukwakheka kwe-compact.

Isinyathelo2:Feedstock - Ukuhlanganiswa kuyinqubo yokuxuba impushana yensimbi nesibophelelo ukuze uthole ukudla okufanayo. Njengoba ubunjalo bempahla yokuphakelayo bunquma izici zokugcinaumkhiqizo owenziwe ngomjovo , lesi sinyathelo senqubo sibaluleke kakhulu. Lokhu kuhilela izici ezihlukahlukene ezifana nendlela nokulandelana kokwengezwa kwe-binder nempushana, izinga lokushisa lokuxuba, nezici zedivayisi yokuxuba.

Isinyathelo3:Ukubumba- I-feedstock iyashisisa futhi ijovwe ngaphansi kwengcindezi ephezulu ingene emgodini wokukhunta, okuvumela ukudalwa kwezakhiwo eziyinkimbinkimbi ngendlela emangalisayo. Ingxenye ibizwa ngokuthi "ingxenye eluhlaza" uma isisusiwe.

Isinyathelo sesi-4:Ukubopha- Ngemuva kokuthi "ingxenye eluhlaza" yenze inqubo elawulwayo yokukhipha i-binder, manje isilungele isigaba esilandelayo. Ingxenye ibizwa ngokuthi "nsundu" uma inqubo yokukhipha imali isiqediwe.

Isinyathelo sesi-5:I-Sintering- kuyisinyathelo sokugcina enqubweni ye-MIM, i-sintering iqeda ama-pores phakathi kwezinhlayiya ze-powder "ezinsundu". Yenza imikhiqizo ye-MIM ifinyelele ukuminyana okugcwele noma eduze nokuminyana okugcwele.inqubo ye-sintering ku-powder metallurgykubaluleke kakhulu.

Isinyathelo6: Okuvamileindlela ye-powder metallurgy ukubumba umjovo wensimbi. Ukwelashwa kwe-post-sintering (ukucindezela ngokunemba, ukugingqika, ukukhishwa, ukucisha, ukucisha ingaphezulu, ukucwiliswa kwamafutha, njll.) kuyadingeka kuma-workpieces anezidingo zokunemba okuphezulu, ubulukhuni obuphezulu, nokumelana nokugqokwa okuphezulu.

I-workpiece izobe ihlanekezelwe ngandlela thize ngesikhathi sokucutshungulwa futhi izodinga ukubunjwa kabusha.Ithuluzi lokubumba elikhona liwumklamo olula futhi lingacubungula futhi lilolonge ucezu olulodwa lomsebenzi ngesikhathi, okuholela ekusebenzeni kahle komsebenzi kanye nezindleko zomkhiqizo ophezulu. Ngaphezu kwalokho, i-tooling yokubunjwa ingasetshenziswa kuphela kuma-workpieces kuze kube usayizi othile; uma usayizi we-workpiece ezobunjwa mkhulu kunalobu bubanzi, angeke isetshenziswe. Ngemuva kwevelu, ithuluzi lidinga ukushintshwa, okwehlisa ngokwengeziwe ukusebenza kahle komsebenzi.

Isinyathelo sesi-7: Ukutholwa okuzenzakalelayo + Ukuhlolwa ngesandla kwemikhiqizo ye-MIM PRODUCT

Isaziso:

ngemuva kwe-Sintering MAY BE

Ngemvaukucula, eminye imisebenzi yesibili

I-JIEHUANG ihlinzeka ngezinqubo eziningi zesibili zokuthuthukisa ukulawula kobukhulu ngemva kokuba izingxenye zakho zingenazo zonke izinto ezibophayo, okuhlanganisa:

Ukwenza imishini

ukulungiswa kwendawo

Izingxenye zingase zihlanekezele futhi ziqale ukwehla noma zihudule phakathi nenqubo yokucwilisa. Izinqubo ezishiwo ngenhla zilungisa lezi zinkinga futhi zibuyisele ingxenye ekwakhiweni kwayo kwasekuqaleni.