ISISOMBULULO

JIEHUANGUkubumba kwe-MIMkunciphisa umatshini ochitha ixesha ngelixa uvelisa iintsimbi ezilula ukuya kwezintsonkothileyo ngokukhawuleza.iindawo zokubumba ze-MIM lukhetho oluhle kakhulu lwesicelo kumashishini ahlukeneyo, kubandakanya i-aerospace, i-automotive, izixhobo zombane, iikhomputha, unyango, amazinyo, kunye nezixhobo ze-orthodontic. Ukuvelisa iindawo ezibalulekileyo ezinobunzima obuqhelekileyo obungaphantsi kwe-100 grams kwaye ubukhulu buqhelekile buyi-0.5~20μm igqibelele kwiMIM(mim yokubumba inaliti yentsimbi), ukubumba iTiMIM (i-titanium yokubumba) kunye nokubumba inaliti yomgubo weceramic. I-JIEHUANG Metal Products ngoku ibonelela ngokujika ngokukhawuleza kwe-3D eprintiweyo iprototype efana ne-MIM-like parts ukuxhasa amalinge eR&D abathengi.

I-MIM yentsimbi yokubumba iinaliti Izinto zokubumba

Ukwenzela imim yokubumba inaliti yentsimbi inkqubo, uluhlu olukhulu ingxubevange metal ziyafikeleleka, Isetyenziswa ikakhulu ukwenza kunye nokusetyenzwa kwesakhiwo kunye nokuhombisa ngokuchanekileyo amalungu mechanical ukuba kuquka iintlobo ngeentlobo Stainless steel, titanium, kunye Zirconia (inaliti yeceramic), ukukhankanya ezimbalwa. UJIEHUANG MIM yingcaphephe kwi:

1.Olu hlobo lwezinto lubandakanya izinto ze-austenitic stainless steel, ezifana ne-316L, i-304 series, njl.,

I-2.precipitation iqinisa uchungechunge lwensimbi engenasici efana ne-17-4PH, i-SUS631 kunye nezinye izinto eziphezulu ze-Stainless steel stainless injection;

I-3.SUS440 i-series ye-martensitic structure ye-stainless steel stainless injection, isetyenziswa ngokubanzi kwi-instrumentation, izixhobo zonyango, i-hardware yokubukela kunye nezinye iinkalo.

Ngokuphathelele izinto zentsimbi yakho , siya kukunika iingcebiso zobungcali ngokusetyenziswa kweemveliso zetsimbi.

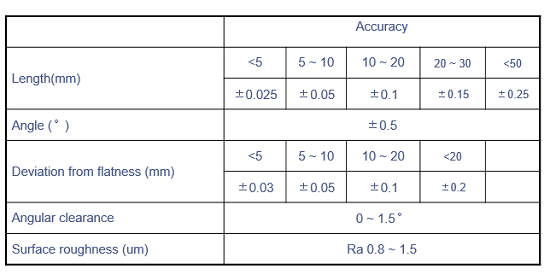

Itshathi yokuNyamezelwa kwesitofu sesinyithi

Ngaba awuqinisekanga ngobungakanani obufanelekileyo beMIM yokubumba indawo yakho? Qinisekisa ukuba nayiphi na inkqubo tooling ukhetha xa ukhetha ainkampani yokubumba inaliti yesinyithi inika amacandelo ahambelanayo ngokufanelekileyo nangokuphindaphindiweyo. Inkqubo yethu yesiko yesixhobo yenzelwe ukwandisa ukusebenza kwakho kwemveliso kunye nokunciphisa iindleko zakho.

Nceda uqhagamshelane nathi !

Inkqubo yokubumba inaliti yesinyithi

Inyathelo1:Isibophelelo - ingundoqo inkqubo yokubumba inaliti yesinyithi. Kwiukubumba inaliti yensimbi engenasici, i-binder ineyona misebenzi mibini isisiseko yokuphucula umbane wokubumba inaliti kunye nokugcina ubume be-compact.

Inyathelo2:Feedstock - Ukudibanisa yinkqubo yokuxuba umgubo wesinyithi kunye ne-binder ukufumana ukutya okufanayo. Ekubeni ubume bezinto zokutya bumisela iimpawu zokugqibelaimveliso isitofu-ebunjiweyo , eli nyathelo lenkqubo libaluleke kakhulu. Oku kubandakanya izinto ezahlukeneyo ezifana nendlela kunye nokulandelelana kwongezwa kwe-binder kunye nomgubo, ukushisa okuxutywayo, kunye neempawu zesixhobo sokuxuba.

Inyathelo3:Ukubumba- I-feedstock iyafudunyezwa kwaye itofwe phantsi koxinzelelo oluphezulu kwisithuba sokungunda, okwenza ukuba kuyilwe izinto ezintsonkothileyo ngokumangalisayo. Icandelo libizwa ngokuba yi "green part" xa sele lisusiwe.

Inyathelo lesi-4:Ukubophelela- Emva kokuba "icandelo eliluhlaza" liqhube inkqubo elawulwayo yokususa i-binder, ngoku ilungele isigaba esilandelayo. Icandelo kubhekiselwa kulo "njengebala elimdaka" nje ukuba inkqubo yokudibanisa igqityiwe.

Inyathelo lesi-5:Sintering- linyathelo lokugqibela kwinkqubo ye-MIM, i-sintering iphelisa i-pores phakathi kwe-"brown" inxalenye yomgubo. Yenza iimveliso ze-MIM zifikelele kuxinaniso olupheleleyo okanye kufutshane noxinaniso olupheleleyo.inkqubo ye-sintering kwi-powder metallurgyibaluleke kakhulu.

Inyathelo6: Eqhelekileyoindlela ye powder metallurgy kukubumba inaliti yentsimbi. Ukunyangwa kwe-Post-sintering (ukucofa ngokuchanekileyo, ukuqengqeleka, ukukhutshwa, ukucima, ukucima umphezulu, ukuntywiliselwa kweoli, njl.

I-workpiece iya kuphazamiseka ngandlela-thile ngexesha le-post-processing kwaye kuya kufuneka ihlaziywe.Isixhobo esikhoyo sokubunjwa siyilo olulula kwaye sinokusebenza kuphela kunye nokubumba i-workpiece enye ngexesha, okukhokelela ekusebenzeni okuphantsi kunye neendleko eziphezulu zemveliso. Ukongeza, izixhobo zokubunjwa zingasetyenziselwa kuphela izixhobo zokusebenza ukuya kubungakanani obuthile; ukuba ubungakanani bomsebenzi oza kubunjwa bukhulu kunolu luhlu, ayinakusetyenziswa. Emva kwexabiso, i-tooling kufuneka itshintshwe, nto leyo iyancipha ngakumbi ukusebenza kakuhle.

Inyathelo lesi-7: Ubhaqo oluzenzekelayo + Ukuhlolwa ngesandla kweemveliso zeMIM PRODUCT

Isaziso:

emva Sintering MAY BE

Emva kokoukucula, eminye imisebenzi yesibini

I-JIEHUANG ibonelela ngeenkqubo ezininzi zesibini zokuphucula ulawulo lomda emva kokuba izinto zakho zikhululekile kuzo zonke izinto ezibophelelayo, kubandakanya:

Umatshini

ukulungiswa komphezulu

Amalungu angagqwesa kwaye aqale ukuhla okanye ukutsala ngexesha lenkqubo yokuntywila. Iinkqubo ezikhankanywe ngasentla zilungisa ezi ngxaki kwaye zibuyisele inxalenye kuyilo lwayo lokuqala.