- Isitofu sesinyithi sokubumba iiNdawo zeMIM

- Umgubo weMetallurgy

- Die Casting

- Ushicilelo lwe-3D

Ibali kunye noMthengi

Isitofu sesinyithi sokubumba iiNdawo zeMIM

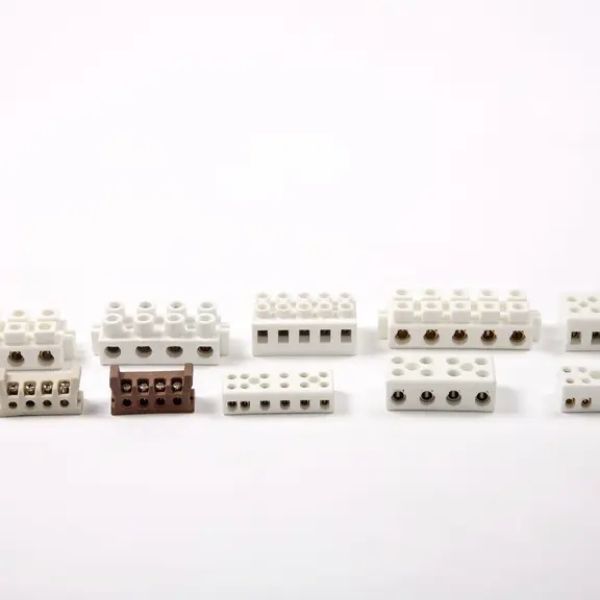

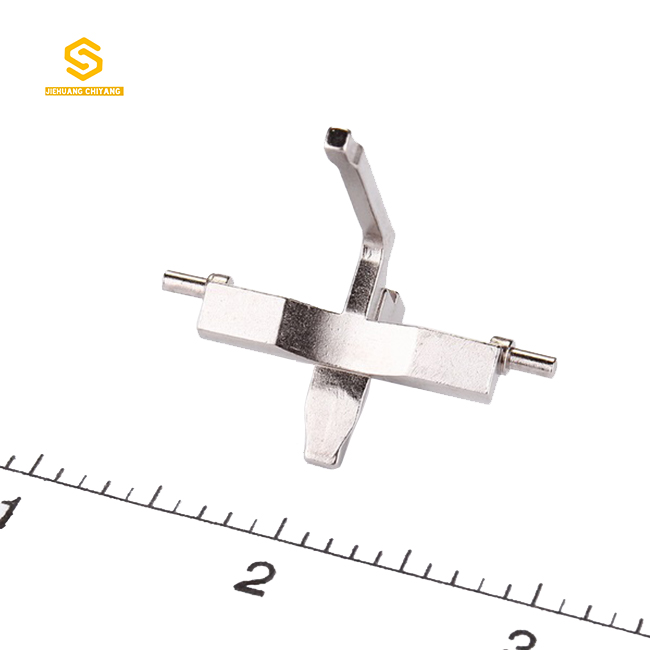

Ukubunjwa kwesitofu sesinyithi (MIM), kwaziwa njengeUkubunjwa kwesitofu somgubo (PIM) , bubuchwephesha bokubumba isinyithi esisebenzisa izixhobo zokubumba iinaliti ukuvelisa zombini iindawo zentsimbi ezisisiseko kunye nezintsonkothileyo ezinokunyamezelana okuqinileyo. I-MIM ingasetyenziswa kumacandelo ahlukeneyo, nangona ezona zingcono zihlala zincinci kwaye zinobunzima obungaphantsi kwe-100 grams, nangona iindawo ezinkulu zicingeleka. Ezinye iindlela zokwenza isinyithi, ezifana nokuphosa utyalo-mali kunye nomatshini, unokutshintshwa yi-MIMinkqubo yokubumba inaliti yesinyithiinkqubo.

Metal Isitofu Molding PartsIzinto eziluncedo:

Iijiyometri ezintsonkothileyo Usetyenziso lwezinto eziphathekayo olusebenzayo

Njengomphumo wokuvelisa kufutshane namacandelo efom yenetha, kukho inkunkuma encinci yezinto eziphathekayo, ngoko ke kuthathwa njengobuchwephesha obuluhlaza.

Ukuphindaphinda

Iimpawu zoomatshini zigqwesile.

Izinto ezizodwa ezidalwe ukuzalisekisa iimfuno zecandelo / zesicelo zisetyenziselwa ukubonelela ngezisombululo ezilungiselelwe.

Ukufumana izisombululo ezipheleleyo zendibano, izixhobo ze-MPP zinokudityaniswa / zidityaniswe kumacandelo ahlukeneyo.

Iimpawu zeempawu eziPhambili zeMIM:

Inkqubo yokubumba inaliti yomgubo bubuchule obuphinda buphinde buphinde buphinde buphinde buphinde buphinde buphinde buphinde buphinde buphinde buphinde buphinde buphinde buphinde jwakhiwe wamacandelo wengxubevange yobushushu obuphezulu.

Metal naliti ukubumba iindawoziphantse zaxinana ngokupheleleyo, zikhokelela kumatshini obalaseleyo, imagnethi, umhlwa, kunye neempawu zokutywinwa zehermetic, kunye nokukwazi ukwenza iinkqubo zesibini ezinje ngokutyabeka, unyango lobushushu, kunye nomatshini.

Iindlela ezintsha zokusebenzisa izixhobo, ezifanayo nezo zisetyenziswa kushishino lokubumba inaliti yeplastiki, zisetyenziselwe ukudala iimilo ezintsonkothileyo.

Isixhobo se-Multi-cavity sisetyenziselwa ukufezekisa ubuninzi obuphezulu.

Ekhaya

Ekhaya