- Qaybaha MIM ee Duridda Birta ah

- Macdanta budada ah

- Dhimashada Jilitaanka

- Daabacaadda 3D

Sheeko la socota Macmiilka

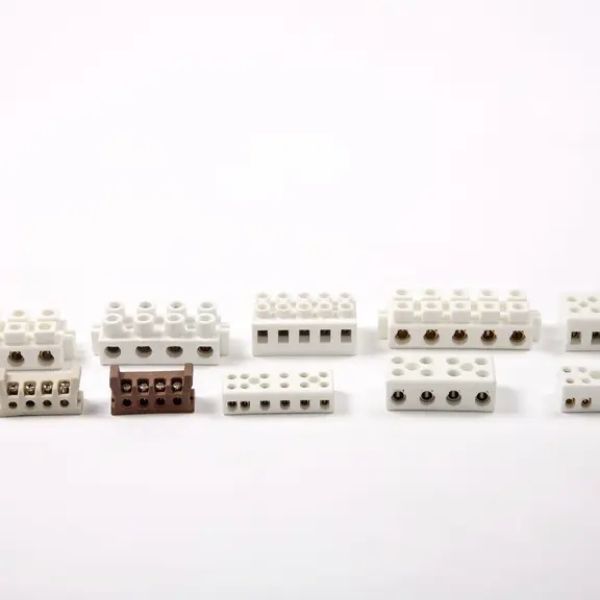

Qalabka MIM

Qalabka lagu dabaqi karoDuritaan bir ah qaabaynta:

Habka MIM waxaa lagu dabaqi karaa noocyo kala duwan oo qalab ah, oo ay ku jiraan birta daawaha hoose, birta aan la taaban karin, birta birta, daawaynta saldhigga nikkel, daawaynta tungsten, daawaha adag, aluminium titanium, alaabta magnetic, Kovar alloy, dhoobada wanaagsan, iwm

Waa maxay nooca alaabooyinka birta ah ee ku habboonHabka MIM:

1. MIM qaybaha MIM sida caadiga ah waa 0.2g - 200g.

2. Bedka la saadaaliyay waa 100 sentimitir oo laba jibbaaran.

3. Saxnaanta cabbirka qaybaha MIM ee ka sarreeya 10MM waa ± 0.5%.

4. Qaybaha MIM dhumucdiisuna waxay tahay 10MM.

5. Cabbirka ugu yar 0.2MM.

Shaxda 1 Agabka MIM ee sida caadiga ah loo isticmaalo iyo goobahooda codsiga:

Habka alaabta | Astaanta Alloy, Halabuurka | Goobta codsiga |

Bir daawaha hoose | Fe-2Ni, Fe-8Ni | Qaybaha kala duwan ee dhismaha baabuurta, mishiinada iyo warshadaha kale |

Bir daxal laheyn | 316L, 17-4PH, 420, 440C Shaxda 2-aad sifooyinka alaabta MIM ee sida caadiga ah loo isticmaalo: | Qalabka caafimaadka, qaybaha daawashada |

Daawaha adag | WC-Co | Dhammaan noocyada mindiyaha, saacadaha, saacadaha |

dhoobada | Al2O3, ZrO2, SiO2 | Qalabka elektiroonigga ah ee IT-ga, waxyaabaha daruuriga ah ee maalinlaha ah, saacadaha iyo saacadaha |

Daawaha culus | W-Ni-Fe,W-Ni-Cu,W-Cu | Warshadaha ciidamada, isgaarsiinta, daruuraha maalinlaha ah |

Titanium alloy | Ti, Ti-6Al-4V | Qaybaha qaab dhismeedka caafimaadka iyo ciidamada |

Qalabka magnetic | Fe, NdFeB, SmCo5, Fe-Si | Qaybaha magnetic kala duwan |

Qalabka birta | CrMo4, M2 | Qalab kala duwan |

Shaxda 2-aad sifooyinka alaabta MIM ee sida caadiga ah loo isticmaalo:

Magacaabista Agabka | Halabuurka Alloy (wt%) |

Xaalad | Cufnaanta ρ (g/cm³) | UTS σ b (Mpa) | YS σ 0.2 (Mpa) | Dheeraynta w (%) |

Adag |

Birta Alloy Low | |||||||

MIM4600 (MIM2200) | 1.5 ~ 2.5% M 0.5% max Fe hadhaaga |

Sintered |

7.50 |

290 |

125 |

40 |

45-65HRB |

| MIM4600 (la habeeyey) (MIM2700) | 6.5 ~ 8.5% M 0.5% ugu badnaan Fe |

Sintered |

7.60 |

410 |

210 |

26 |

70 ~ 90HRB |

|

MIM4605 | Ni 1.5 ~ 2.5% Mo 0.2 ~ 0.5% C 0.4 ~ 0.6% Fe dheelitirka |

Sintered |

7.50 |

415 |

255 |

15 |

65-85HRB |

kulaylka lagu daweeyay | 7.50 | 1655 | 1480kii | 2 | 45-50HRC | ||

|

MIM4140 | 0.75 ~ 1.25% Cr 0.75 ~ 1.25% Isniin 0.75% ugu badnaan C 0.3 ~ 0.5% Fe dheelitirka |

Sintered |

7.50 |

820 |

620 |

10 |

70 ~ 100HRB |

|

kulaylka lagu daweeyay |

7.50 |

1400 |

820 |

5 |

45 ~ 45HRC | ||

Bir daxal laheyn | |||||||

|

ME SS316L | C 0.03% ugu badnaan Ni 10 ~ 14% Mo 2 ~ 3% Cr 18 ~ 20% Fe dheelitirka |

Sintered |

7.75 |

500 |

250 |

4 |

65-85HRB |

|

MIM SS304 | C 0.08% ugu badnaan Ni 8 ~ 10% Cr 18 ~ 20% Fe dheelitirka |

Sintered |

7.65 |

480 |

270 |

35 |

65-85HRB |

|

ME SS420 | C 0.2 ~ 0.4% Cr 12 ~ 14% Fe dheelitirka | kulaylka lagu daweeyay |

7.40 |

1310 |

11500 |

6 |

40 ~ 45HRC |

|

ME 17-4PH | C 0.07% ugu badnaan Cr 15.5 ~ 17.5% Iyadoo 3 ~ 5% Ni 3 ~ 5% Nb 0.15 ~ 0.45% Fe dheelitirka |

Sintered |

7.50 |

900 |

730 |

6 |

20 ~ 28HRC |

|

kulaylka lagu daweeyay |

7.50 |

1185 |

1090 |

5 |

32 ~ 42HRC | ||

ME SS310S |

| Sintered | 7.70 | 520 | 205 | 40 | 80 ~ 100HRB |

Shaxda 3 Isbarbardhigga MIM iyo hababka kale:

Duritaan birta qaabaynta waa cusubhabka biraha budada ah , waxa ay soo saari kartaa cufnaanta sare iyo qaabka adag qaybo sintered iyada oo aan mashiin. Iyada oo leh sifooyinka gaarka ah ee alaabta MIM, MIM waxay awood u leedahay inay soo saarto qaybo bir ah oo sax ah oo loogu talagalay badeecooyin kala duwan, oo ay ku jiraan baabuurta, telefoonnada gacanta, qalabka gacanta, qalabka ilkaha, qalabka pneumatic, qalabka gacanta, qalabka qalliinka, alaabta ciyaaraha iyo kombiyuutarada laptop. Walxaha biraha ah ee sida caadiga ah loo isticmaalo habka MIM waa birta aan birta lahayn, birta daawaha ah iyo qalabka birta jilicsan.

Jiehuang MIM, waxaanu ku takhasusay qaybaha MIM ee birta aan fiicnayn, walxo bir ah oo hooseeya.

Jiehuang MIM waxay soo saari kartaa saxQaybaha MIMagab kala duwan hadba baahidaada.

Guriga

Guriga