- Qaybaha MIM ee Duridda Birta

- Macdanta budada ah

- Dhimashada Jilitaanka

- Daabacaadda 3D

Sheeko la socota Macmiilka

Birta Birta ee Titanium Molding (TiMIM)

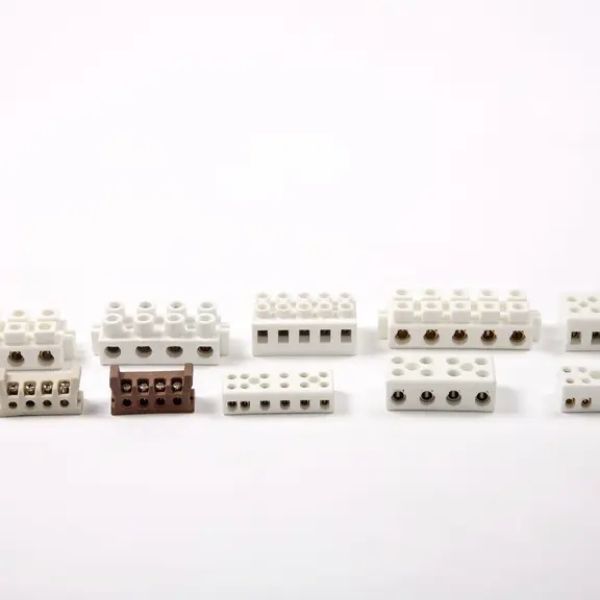

Biraha, Aloyiska, iyo ceramics-ka ayaa ka mid ah agabka ku jira MIM Molding portfolioBirta Birta ee Titanium Molding (TiMIM)awood u leeyahay inuu wax ka beddelo.

Si loo abuuro kayd quudin oo lagu farsamayn karo mishiinada qaabaynta duritaanka, TiMIM waxay ka kooban tahay isku darka birta Titanium budada ah iyo walaxda xidhaha. Marka laga soo tago qaybaha birta ee caadiga ah ee Titanium-ka lagu farsameeyo, qaabaynta durista birta waxay awood u siinaysaa qaybaha Titanium-ka adag in ay si sax ah u qaabeeyaan hal hawlgal iyo mug sare.

Dhumucda gidaarada kala duwan ee ilaa 0.125′′ ama 3mm waa sifooyin laga heli karoQaybaha TiMIM . Intaa waxaa dheer, qaybaha TiMIM waa la dhammeyn karaamashiinhaddii loo baahdo oo qaado daawaynta dusha kala duwan, sida anodizing iyo electropolishing.

Titanium alloy waa bir muhiim ah oo la sameeyay bartamihii qarnigii 20aad, sababtoo ah cufnaanta hoose, xoog gaar ah oo sarreeya, caabbinta daxalka wanaagsan, iska caabinta kulaylka sare, malab la'aan, waxqabadka alxanka wanaagsan iyo sifooyin kale oo aad u fiican, oo si ballaaran loo isticmaalo hawada, baabuurta. , bioengineering (waafaqid wanaagsan), saacadaha, alaabta isboortiga, ilaalinta deegaanka iyo beeraha kale, laakiin titanium iyo titanium alloy waxqabadka machining waa liidata, Kharashka wax soo saarka sare xaddido codsigeeda warshadaha, gaar ahaan qaybaha adag.

Tiknoolajiyada PIM ee Iskuduridda budada ah waa tignoolajiyada ugu dhaqsaha badan ee kobcinta birta budada ah, waxaana loo arkaa inay tahay tignoolajiyada diyaarinta qaybta ugu kulul. Tiknoolajiyadu waa isku-darka tikniyoolajiyada samaynta birta budada dhaqameed iyo tikniyoolajiyadda duritaanka caagga ah, ma aha oo kaliya faa'iidooyinka geeddi-socodka birta budada caadiga ah ee geeddi-socod yar, goyn la'aan ama goyn ka yar, faa'iidooyin dhaqaale oo sarreeya, iyo ka gudubka habka birta budada dhaqameed ee wax yar cufnaanta, walxo aan sinnayn, sifooyin farsamo oo hooseeya, ma fududa in la sameeyo gidaar khafiif ah, qaybo kakan qaabdhismeedka mim ah. Waxay si gaar ah faa'iido u leedahay diyaarinta alaabta samaynta nadiifka ah ee u dhow oo leh joomatari adag, qaab-dhismeedka lebbiska iyo waxqabadka sare. Joomatari, sifooyinka farsamada iyo saxnaanta sheyga ee habka qaabaynta budada titanium alloy waxaa lagu gaari karaa taas oo aan lagu heli karin hab dhaqameed. Si kastaba ha noqotee, birta titanium waxay leedahay waxqabad sare waxayna fududahay in ay la falgasho kaarboon, oksijiin iyo nitrogen si ay u abuurto TiC, TiO2, TiN iyo xeryahooda kale, taas oo adkeynaysa in la hagaajiyo cufnaanta sintay iyo sifooyinka farsamada.

Guud ahaan, qaybaha mim ha marin daawaynta ka dib, iyo sintering inta badan waxaa loo isticmaalaa habka ugu dambeeya eeHabka MIM , kaas oo leh saamaynta cufnaanta iyo sifooyinka kiimikada isku midka ah ee walxaha alloying. Tusaale ahaan, markii Obasi uu sintered Ti-6AI-4V muunado, heerkulka sintering ahaa 1520-1680 degrees Celsius.

Waqtigan xaadirka ah, qaabeynta durista daawaynta titanium waxaa si weyn loogu isticmaalaa hawada hawada, markabka dagaalka, baabuurta, kiimikooyinka iyo beeraha petrochemical, iyo qaabeynta duridda daawaha titanium waxay leedahay rajooyin codsi oo ballaaran. Maraykanku waxa uu qaatay qaybo badan oo ka mid ah qaybaha dhisme ee daawaynta titanium-ka ee garoonka hawada sare. Tusaale ahaan, daawaynta titanium ee loo isticmaalo F-22, jiilka afraad ee diyaaradaha dagaalka ee Maraykanka, waxay ka dhigan tahay 38.8% qaabka diyaaradaha; Isticmaalka titanium ee Rah-66, qoryaha, waa 12.7%; Isticmaalka titanium ee TF31, aeroengine, iyo isticmaalka titanium ee dayax gacmeedka Apollo ayaa gaaraya 1180KG. Marka la eego suurtogalnimada, daawaynta titanium ayaa si ballaaran loogu isticmaali doonaa warshadaha madaniga ah, gaar ahaan qaybaha baabuurta, qaybaha qalabka caafimaadka, qaybaha bayoolojiga.

Alloy Titanium waxaa loo isticmaalaa in valves engine, isku xirka ulo, crankshafts iyo ilo, taas oo aan hoos u dhigi kartaa oo kaliya miisaanka gaariga, kordhin nolosha gaariga, laakiin sidoo kale hagaajinaysaa xawaaraha. Goobta madaniga ah, qiimaha daawaynta titanium waa in uu ahaado tixgelinta ugu horeysa, kharashka wax soo saarka, wax-qabadka sare ee titanium alloy qaybaha habka waa:

1. Baro aluminium titanium oo ku habboon shuruudaha gaarka ah ee TiMIM

2. Samee tignoolajiyada cusub ee wax soo saarka budada qiimo jaban ee alaabta ceeriin ee Ti-MIM

3. Kor u qaad cabbirada nidaamka Ti-MIM si loo xakameeyo tayada badeecada

4. Samee nidaam cusub oo qosol leh Ti-MIM

5. Samee jaangooyooyinka Ti-MIM ee baabuurta, maraakiibta iyo meelaha kale, iyo kor u qaadida isticmaalka baaxadda leh ee titanium iyo titanium alloy-ka-durista budada

Mashiinnada qaabaynta koronto ee casriga ah, foornooyinka joogtada ah iyo dufcada debind iyo foornooyinka sintay, nidaamyada kala saarida dareeraha, 5- dhidibka CNC machining iyo xarumaha shiida, kilns dhoobada, qadaadiic, laser etching / xardhan, iyo shaybaarada kormeerka oo dhan waxaa maamula shirkadda JH MIM. Adeegyo qiimo leh oo kala duwan ayaa sidoo kale bixiya JH MIM, oo ay ku jiraan wax-soo-saarka degdega ah, dhejinta, alxanka laysarka, daaweynta kulaylka, dhamaystirka dusha sare iyo dhalaalidda, isu-ururinta, xidhmada kama dambaysta ah, iyo in ka badan. Iyada oo qayb ka ah qiyamka asaasiga ah ee JH MIM, nashqadeynta caawinta kartida wax soo saarka ayaa lagu bixiyaa lacag la'aan. Ganacsigu wuxuu kormeeraa naqshadaynta iyo dhismaha hal iyo godad badan, orodyahan kulul, iyo caaryada aan xidhnayn ee dukaamada qalabka guriga ee u dhow.

Guriga

Guriga