- Gutera Ibyuma Kubumba MIM Ibice

- Ifu ya Metallurgie

- Gupfa

- Icapiro rya 3D

Inkuru hamwe n'umukiriya

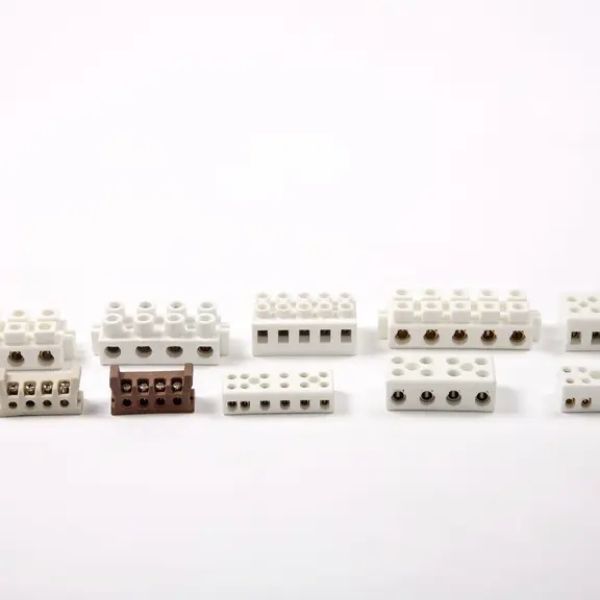

Ibikoresho bya MIM

Ibikoresho bikoreshwa kuriKubumba ibyuma:

Inzira ya MIM irakoreshwa muburyo butandukanye bwibikoresho, birimo ibyuma bito bito, ibyuma bidafite ingese, ibyuma byifashishwa, nikel base alloy, tungsten alloy, alloy alloy, titanium alloy, ibikoresho bya magneti, Kovar alloy, ceramics nziza, nibindi

Ni ubuhe bwoko bw'ibyuma bikwiranye naMIM inzira:

1. Uburemere bwa MIM mubusanzwe ni 0.2g - 200g.

2. Agace kateganijwe ni santimetero 100.

3. Ibice bya MIM ubunini buri hejuru ya 10MM ni ± 0.5%.

4. Ibice bya MIM uburebure bwurukuta ni 10MM.

5. Ingano ntarengwa 0.2MM.

Imbonerahamwe 1 Ibikoresho bisanzwe bikoreshwa na MIM hamwe nibisabwa:

Sisitemu y'ibikoresho | Ikirangantego, ibihimbano | Umwanya wo gusaba |

Icyuma gike | Fe-2Ni 、 Fe-8Ni | Ibice bitandukanye byuburyo bwimodoka, imashini nizindi nganda |

Ibyuma | 316L 、 17-4PH 、 420 、 440C Imbonerahamwe 2 Ibyiza byibikoresho bisanzwe bikoreshwa na MIM: | Ibikoresho byubuvuzi, kureba ibice |

Umuti ukomeye | WC-Co | Ubwoko bwose bw'icyuma, amasaha, amasaha |

ceramic | Al2O3 、 ZrO2 、 SiO2 | IT electronics, ibikenerwa bya buri munsi, amasaha nisaha |

Amavuta akomeye | W-Ni-Fe 、 W-Ni-Cu 、 W-Cu | Inganda za gisirikare, itumanaho, ibikenerwa buri munsi |

Titanium | Ti 、 Ti-6Al-4V | Ibice byubuvuzi nigisirikare |

Ibikoresho bya rukuruzi | Fe 、 NdFeB 、 SmCo5 、 Fe-Si | Ibice bitandukanye bya magneti |

Icyuma | CrMo4 、 M2 | Ibikoresho bitandukanye |

Imbonerahamwe 2 Ibyiza byibikoresho bisanzwe bikoreshwa na MIM:

Kugenera Ibikoresho | Amavuta (wt%) |

Imiterere | Ubucucike ρ (g / cm³) | UTS σ b (Mpa) | YS σ 0.2 (Mpa) | Kurambura w (%) |

Gukomera |

Amashanyarazi make | |||||||

MIM4600 (MIM2200) | Kuri 1.5 ~ 2.5% Mo 0.5% max Fe impirimbanyi |

Icyaha |

7.50 |

290 |

125 |

40 |

45 ~ 65HRB |

| MIM4600 (yahinduwe) (MIM2700) | Kuri 6.5 ~ 8.5% Mo 0.5% max Fe impirimbanyi |

Icyaha |

7.60 |

410 |

210 |

26 |

70 ~ 90HRB |

|

MIM4605 | Ni 1.5 ~ 2.5% Mo 0.2 ~ 0.5% C 0.4 ~ 0,6% Kuringaniza |

Icyaha |

7.50 |

415 |

255 |

15 |

65-85HRB |

Ubushyuhe | 7.50 | 1655 | 1480 | 2 | 45 ~ 50HRC | ||

|

MIM4140 | Kuri 0,75 ~ 1.25% Cr 0,75 ~ 1.25% Ukwezi 0,75% max C 0.3 ~ 0.5% Kuringaniza |

Icyaha |

7.50 |

820 |

620 |

10 |

70 ~ 100HRB |

|

Ubushyuhe |

7.50 |

1400 |

820 |

5 |

45 ~ 45HRC | ||

Ibyuma | |||||||

|

NJYE SS316L | C 0.03% max Ni 10 ~ 14% Mo 2 ~ 3% Cr 18 ~ 20% Kuringaniza |

Icyaha |

7.75 |

500 |

250 |

4 |

65 ~ 85HRB |

|

MIM SS304 | C 0.08% max Ni 8 ~ 10% Cr 18 ~ 20% Kuringaniza |

Icyaha |

7.65 |

480 |

270 |

35 |

65 ~ 85HRB |

|

NJYE SS420 | C 0.2 ~ 0.4% Cr 12 ~ 14% Kuringaniza | Ubushyuhe |

7.40 |

1310 |

11500 |

6 |

40 ~ 45HRC |

|

NJYE 17-4PH | C 0.07% max Cr 15.5 ~ 17.5% Hamwe na 3 ~ 5% Ni 3 ~ 5% Nb 0.15 ~ 0.45% Kuringaniza |

Icyaha |

7.50 |

900 |

730 |

6 |

20 ~ 28HRC |

|

Ubushyuhe |

7.50 |

1185 |

1090 |

5 |

32 ~ 42HRC | ||

NJYE SS310S |

| Icyaha | 7.70 | 520 | 205 | 40 | 80 ~ 100HRB |

Imbonerahamwe 3 Kugereranya hagati ya MIM nibindi bikorwa:

Gutera ibyuma byatewe ni bishyaifu ya metallurgie inzira , irashobora kubyara ubucucike bwinshi nuburyo bugoye bwacumuye ibice bitarinze gutunganywa. Hamwe nimiterere yihariye yibikoresho bya MIM, MIM ibasha gukora ibyuma bisobanutse neza kubicuruzwa bitandukanye, birimo imodoka, terefone zigendanwa, ibikoresho byamaboko, ibikoresho by amenyo, ibikoresho bya pneumatike, ibikoresho byamaboko, ibikoresho byo kubaga, ibicuruzwa bya siporo na mudasobwa zigendanwa. Ibyuma bikoreshwa cyane mubikorwa bya MIM ni ibyuma bidafite ingese, ibyuma bivanze hamwe nibikoresho byoroshye bya magneti.

Jiehuang MIM, tuzobereye mu bice bya MIM by'ibyuma bitagira umwanda, ibikoresho byo mu cyuma gito.

Jiehuang MIM irashobora gukora nezaIbigize MIMy'ibikoresho bitandukanye ukurikije ibyo ukeneye.

Murugo

Murugo