- Metal Injection Molding MIM Parts

- Powder Metallurgy

- Die Casting

- 3D Printing

Story With Customer

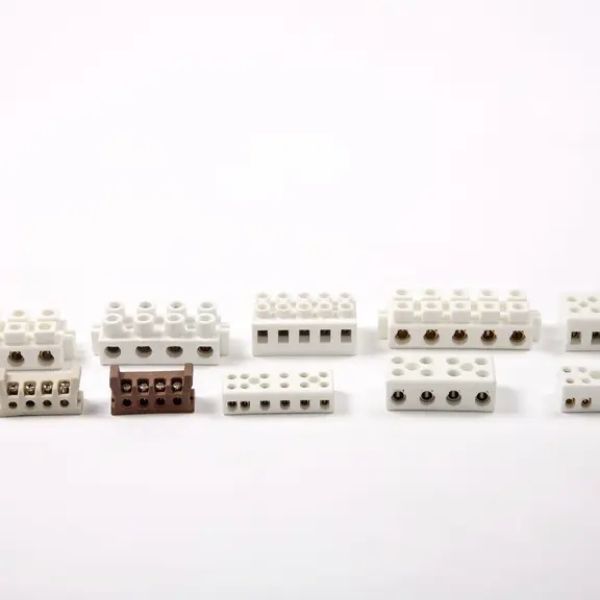

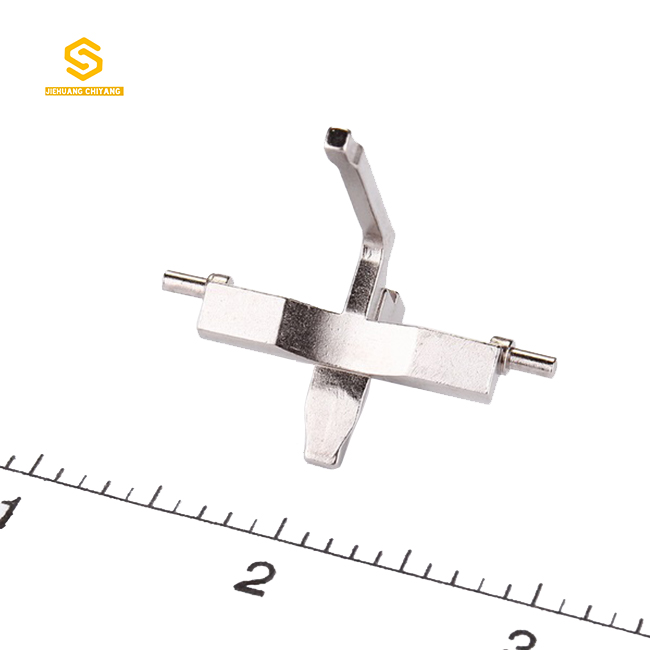

Metal Injection Molding MIM Parts

Metal Injection Molding (MIM), also known as Powdered Injection Molding (PIM), is a sophisticated metal forming technology that use injection molding equipment to produce both basic and complicated metal parts with tight tolerances. MIM can be utilized on a variety of components, although the best ones are often small and weigh less than 100 grams, however larger parts are conceivable. Other metal forming techniques, such as investment casting and machining, can be replaced by the MIM metal injection molding process process.

Metal Injection Molding Parts Advantages:

Geometries that are complicatedMaterial utilization that is efficient

As a result of manufacturing near net form components, there is less material waste, therefore it is considered a green technology.

Repeatability

Mechanical properties are excellent.

Unique materials created to fulfill component/application requirements are used to provide customized solutions.

For complete assembly solutions, MPP materials can be brazed/joined to a variety of components.

MIM Process Key Attributes:

Powder injection molding process is a reproducible technique for complex high-temperature alloy components.

Metal injection molding parts are nearly completely dense, resulting in outstanding mechanical, magnetic, corrosion, and hermetic sealing qualities, as well as the ability to execute secondary processes such as plating, heat treatment, and machining.

Innovative tooling techniques, similar to those used in the plastic injection molding industry, are employed to create complex shapes.

Multi-cavity tooling is used to achieve high quantities.