- Metal Allurar Molding MIM Parts

- Powder Metallurgy

- Mutuwar Casting

- 3D Bugawa

Labari Tare da Abokin Ciniki

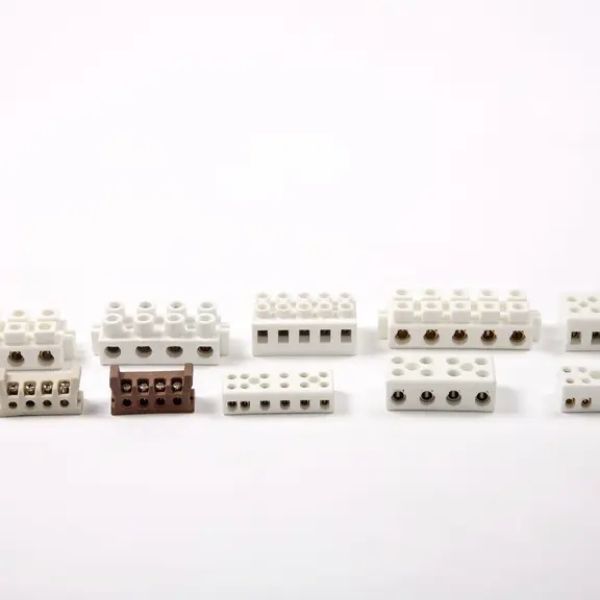

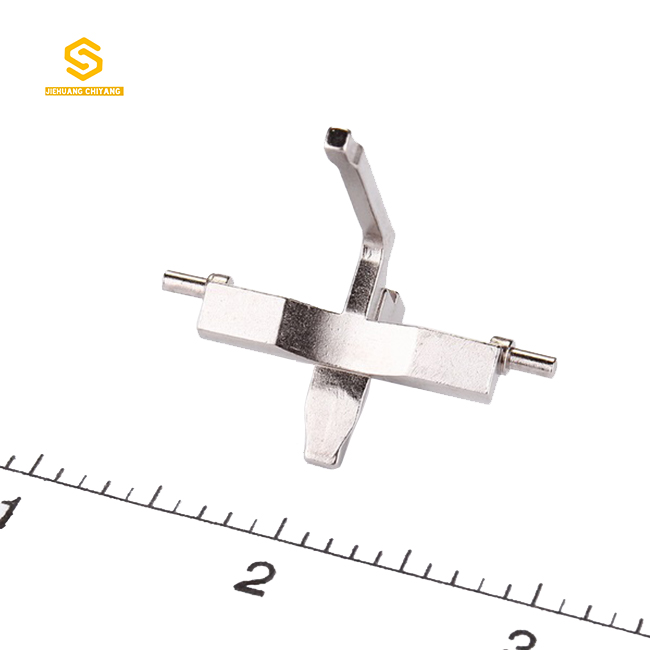

Metal Allurar Molding MIM Parts

Ƙarfe Molding (MIM), kuma aka sani daFoda Molding (PIM) , fasaha ce mai ƙwaƙƙwarar ƙarfe mai ƙira wacce ke amfani da kayan gyare-gyaren allura don samar da sassan ƙarfe na asali da sarƙaƙƙiya tare da matsananciyar haƙuri. Ana iya amfani da MIM akan abubuwa daban-daban, kodayake mafi kyawun yawanci ƙanana ne kuma suna auna ƙasa da gram 100, duk da haka manyan sassa suna iya yiwuwa. Sauran dabarun ƙirƙira ƙarfe, kamar simintin saka hannun jari da injina, ana iya maye gurbinsu da MIMkarfe allura gyare-gyaren tsaritsari.

Ƙarfe na Ƙarfe Molding PartsAmfani:

Geometries waɗanda ke da sarƙaƙƙiyar amfani da kayan aiki masu inganci

A sakamakon masana'antu kusa da nau'in nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i) nau'i-nau'.

Maimaituwa

Mechanical Properties suna da kyau kwarai.

Ana amfani da kayan aiki na musamman da aka ƙirƙira don cika buƙatun sashi / aikace-aikacen don samar da mafita na musamman.

Don cikakkun hanyoyin haɗin kai, kayan MPP na iya zama brazed/haɗe zuwa sassa daban-daban.

Babban Halayen Tsarin MIM:

Foda allura gyare-gyare tsari ne mai reproducible dabara ga hadaddun high-zazzabi gami gami.

Karfe allura sassakusan gaba ɗaya mai yawa, yana haifar da ƙwararrun injiniyoyi, Magnetic, lalata, da halayen rufewar hermetic, da kuma ikon aiwatar da matakai na biyu kamar plating, magani mai zafi, da machining.

Sabbin dabarun kayan aiki, kama da waɗanda aka yi amfani da su a masana'antar gyare-gyaren filastik, ana amfani da su don ƙirƙirar sifofi masu rikitarwa.

Ana amfani da kayan aiki da yawa don cimma adadi mai yawa.

Gida

Gida