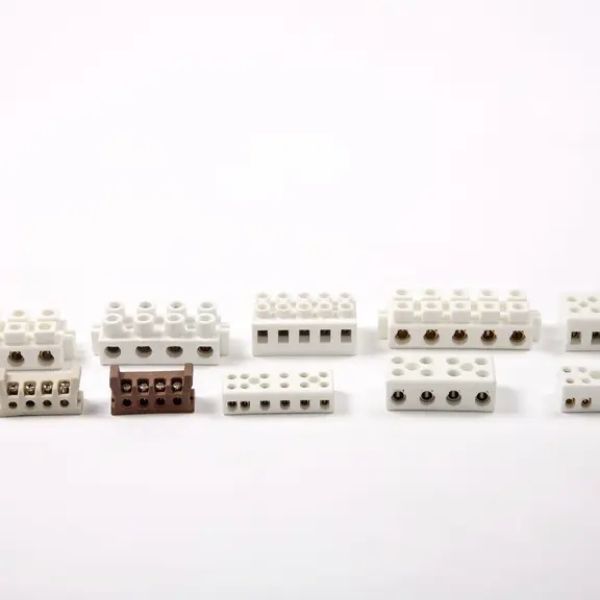

- Metal Injection Molding MIM Parts

- Powder Metallurgy

- Die Casting

- 3D Printing

Story With Customer

Titanium Metal Injection Molding (TiMIM)

Stainless steels, alloys, and ceramics are among the materials in the MIM Molding portfolio that Titanium Metal Injection Molding (TiMIM) is capable of molding.

In order to create a feedstock that can be processed by injection molding machinery, TiMIM entails combining powdered Titanium metal with a binder substance. As opposed to conventional Titanium machined metal components, metal injection molding enables complex Titanium parts to be precisely molded in a single operation and in high volume.

Undercuts and varied wall thickness up to 0.125′′ or 3mm are features that can be found in TiMIM parts. Additionally, TiMIM parts can be finishedmachined if required and take a variety of surface treatments, such as anodizing and electropolishing.

Titanium Metal Injection Molding Parts Made By JHMIM

Titanium alloy is an important metal developed in the middle of the 20th century, because of its low density, high specific strength, good corrosion resistance, high heat resistance, no magnetic, good welding performance and other excellent properties, widely used in aerospace, automotive, bioengineering (good compatibility), watches, sporting goods, environmental protection and other fields, but titanium and titanium alloy machining performance is poor, High manufacturing costs limit its industrial application, especially in complex parts.

Powder Injection Molding PIM technology is the fastest developing technology in powder metallurgy, and it is regarded as the hottest component preparation technology. The technology is a combination of traditional powder metallurgy forming technology and plastic injection molding technology, not only has the advantages of conventional powder metallurgy process less process, no cutting or less cutting, high economic benefits, and overcome the traditional powder metallurgy process of low material density, uneven material, low mechanical properties, not easy to form thin wall, complex structural mim components.

It is especially advantageous in the preparation of near-clean forming products with complex geometry, uniform structure and high performance. The geometry, mechanical properties and product accuracy of titanium alloy powder injection molding process can be achieved which can not be obtained by traditional process. However, titanium metal has high activity and is easy to react with carbon, oxygen and nitrogen to generate TiC, TiO2, TiN and other compounds, which makes it difficult to improve the sintering density and mechanical properties.

In general, mim components do not undergo post-treatment, and sintering is often used as the last process of MIM process, which has the effect of densification and uniform chemical properties of alloying elements. For example, when Obasi sintered Ti-6AI-4V samples, the sintering temperature was 1520-1680 degrees Celsius.

JHMIM titanium molding machine

At present, titanium alloy injection molding is widely used in aerospace, warship, automobile, chemical and petrochemical fields, and titanium alloy injection molding has broad application prospects. The United States has adopted a large number of titanium alloy structural parts in the aerospace field.

For example, the titanium alloy used in F-22, the fourth-generation fighter jet of the United States, accounts for 38.8% of the aircraft structure; titanium consumption of Rah-66, the gunship, is 12.7%; titanium consumption of TF31, the aeroengine, and titanium consumption of Apollo spacecraft reach 1180KG. In terms of potential, titanium alloy will be more widely used in the civil industry, especially automotive parts, medical device parts, biological graft parts.

Titanium alloy is used in engine valves, connecting rods, crankshafts and springs, which can not only reduce the weight of the car, extend the life of the car, but also improve the speed. For the civil field, titanium alloy price must be the first consideration, production cost, high performance titanium alloy injection parts of the way are:

- Study titanium alloys suitable for the special requirements of TiMIM

- Develop new low-cost powder production technology for Ti-MIM raw materials

- Optimize Ti-MIM process parameters to control product quality

- Develop new funny Ti-MIM bonding system

- Develop Ti-MIM standards for automobiles, ships and other fields, and promote the large-scale use of titanium and titanium alloy powder injection molding

Modern electric molding machines, continuous and batch debind and sintering furnaces, solvent debinding systems, 5-axis CNC machining and grinding centers, ceramic kilns, coining, laser etching/engraving, and inspection labs are all operated by JH MIM firm.

A full range of value-added services are also offered by JH MIM , including quick prototyping, plating, laser welding, heat treatment, surface finishing and polishing, assembly, final pack out, and more. As part of JH MIM's core values, design for manufacture ability help is offered without charge. The business oversees the design and construction of single and multi-cavity, hot runner, and unscrewing molds at nearby domestic tool shops.