SOLUTION

JIEHUANG MIM molding reduces time-consuming machining while producing simple to complex metal parts quickly. MIM molding parts are excellent choices for application in a variety of industries, including aerospace, automotive, appliances, computers, medical, dental, and orthodontic equipment. Producing crucial parts with typical weights of less than 100 grams and the size is generally 0.5~20μm is perfect for MIM(mim metal injection molding) , TiMIM molding(molding titanium) and ceramic powder injection molding. JIEHUANG Metal Products now offers quick-turn 3D printed prototype MIM-like parts to support customers' R&D initiatives.

MIM metal injection moulding Materials

For the mim metal injection molding process, a large range of metal alloys are accessible, It is mainly used for the manufacture and processing of structural and decorative precision mechanical parts that including various kinds of Stainless steel, titanium, and Zirconia(ceramic injection), to mention a few. JIEHUANG MIM is an expert in:

1.This type of material includes austenitic stainless steel materials, such as 316L, 304 series, etc.,

2.precipitation hardening stainless steel series such as 17-4PH, SUS631 and other high Strength stainless steel injection materials;

3.SUS440 series martensitic structure stainless steel injection materials, are widely used in instrumentation, medical equipment, watch hardware and other fields.

Regarding the material of your metal parts , we will give you professional advice according to the use of the metal products.

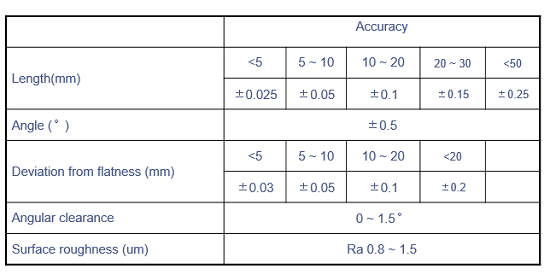

Metal Injection Molding Tolerance Chart

Are you unsure of the proper size for MIM molding your part? Make sure that whatever tooling process you select when choosing a metal injection molding company delivers consistent components effectively and repeatedly. Our traditional tooling procedure is made to increase your production efficiency and decrease your costs.

Please contact us !

Metal injection molding process

Step1: Binder- the core of metal injection molding process. In stainless steel injection molding, the binder has the two most basic functions of enhancing fluidity for injection molding and maintaining the shape of the compact.

Step2:Feedstock - Compounding is the process of mixing metal powder with a binder to obtain a uniform feed. Since the nature of the feed material determines the properties of the final injection-molded product, this process step is very important. This involves various factors such as the way and sequence of addition of binder and powder, the mixing temperature, and the characteristics of the mixing device.

Step 3:Molding- The feedstock is heated and injected under high pressure into a mold cavity, enabling the creation of incredibly intricate structures. The component is referred to as a "green part" once it has been removed.

Step 4:Debinding-After the "green component" has undergone a controlled procedure to remove the binder, it is now ready for the next phase. The component is referred to as "brown" once the debinding process is finished.

Step 5:Sintering- is the last step in the MIM process, sintering eliminates the pores between the “brown” part powder particles. Make MIM products reach full densification or close to full densification. sintering process in powder metallurgy is very important.

Step 6: The typical powder metallurgy method is metal injection molding. Post-sintering treatment (precision pressing, rolling, extrusion, quenching, surface quenching, oil immersion, etc.) is necessary for workpieces with high precision requirements, high hardness, and high wear resistance.

The workpiece will be somewhat distorted during the post-processing and will need to be reshaped.The existing shaping tooling is of a simple design and can only process and shape one workpiece at a time, which leads to low work efficiency and high product costs. In addition, the shaping tooling can only be used for workpieces up to a certain size; if the size of the workpiece to be shaped is larger than this range, it cannot be used. After the value, the tooling needs to be replaced, which further lowers job efficiency.

Step 7: Automated detection + Manual inspection of products MIM PRODUCT

Notice:

after Sintering MAY BE

After sintering, further secondary operations

JIEHUANG provides numerous secondary processes to enhance dimensional control after your components are totally free of all binding material, including:

Machining

surface preparation

Parts may distort and begin to droop or drag during the sintering process. The procedures mentioned above fix these problems and bring the part back to its original design.