- Metal Injection Molding MIM Parts

- Powder Metallurgy

- Die Casting

- 3D Printing

Story With Customer

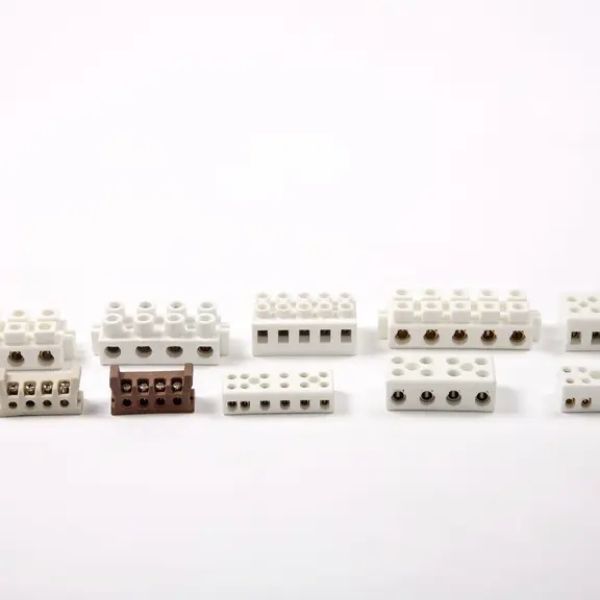

Ceramic Injection Molding

Ceramic Injection Molding CIM is ideal for near net-shape, high-volume production of complex, tight-tolerance ceramic components. Ceramic Injection Molding offers significant advantages over conventional forming methods.

Ceramic injection molding is a cutting-edge technology that is used to create high-precision components in medium to large quantities that are created to exact client specifications. It is a crucial component of many industries. More robust, resilient, and hard than plastic molding or machined steel parts, ceramic components have a wide range of applications.

Therefore, please consider our knowledgeable staff situated in China Cixi if you're considering ceramic material for your part requirements. If you are not familiar with the ceramic injection molding procedure, you can find out what it comprises specifically and how it might help your business.

Advantages Of Ceramic injection molding

CIM technology is particularly useful when conventional machining techniques are prohibitively expensive or unable to complete the task. It is perfect for complex-shaped items where high production quantities and reliable quality are essential. The products made by CIM have very thin grain structures and exceptional surface finishes, coming very close to theoretical densities thanks to the use of sub-micron ceramic powder.

Applications Of Ceramic injection molding

The CIM process has essentially endless applications. Ceramic produces items that are highly corrosion resistant, wear resistant, and have a long lifespan due to its high flexural strength, hardness, and chemical inertness. The electronic assembly, tool, optical, dentistry, telecommunications, instrumentation, chemical plant, and textile sectors all use ceramic materials.

Jiehuang MIM as one of the top Ceramic Injection Molding companies has 15 years of research and development, design, production experience!