- Metal Injection Molding MIM Parts

- Powder Metallurgy

- Die Casting

- 3D Printing

Story With Customer

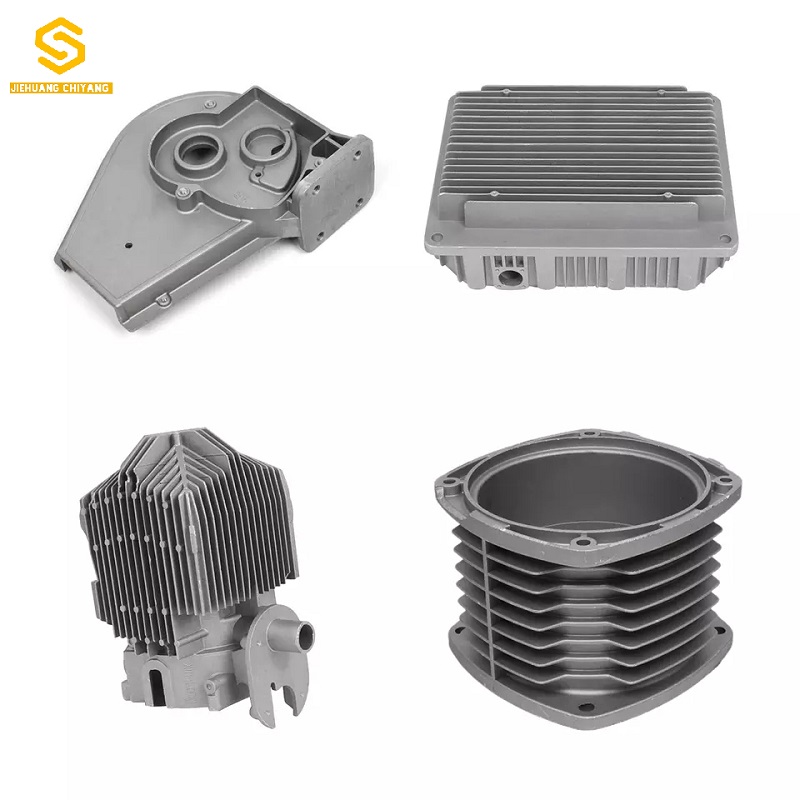

Die Casting

Die casting is a commercial casting process used to create cast parts out of brass, aluminum, zinc, or magnesium. Most automotive parts of new energy electric vehicles use aluminum die-casting process.High pressure aluminum die casting is used to press th molten metal into the die, where it solidifies and is then automatically expelled. There are numerous cavities in a diecan for die casting. Due to the high production of the dies, series of anywhere between 300 and 400,000 molded pieces can be produced, depending on the die. Die casting enables the production of items with incredibly thin walls, smooth surfaces, and edges. Die casting is the ideal casting method for complicated components and demanding applications because to its high strength, excellent dimensional accuracy, and reproducibility, both in terms of quality and cost.

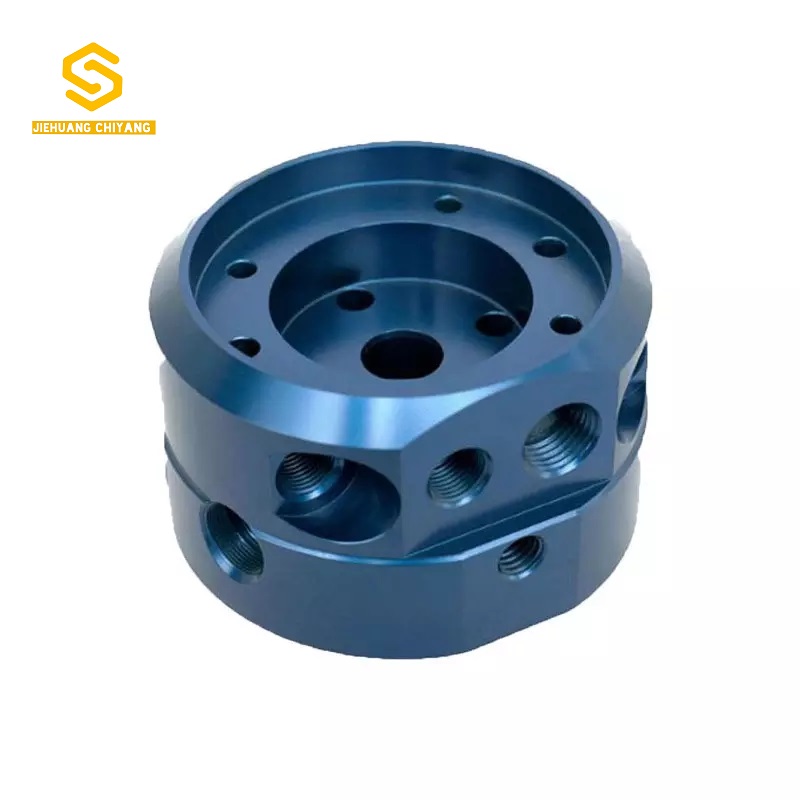

JieHuang as aluminum die casting manufacturer china has high-quality dies for small and medium-sized batches up to 50,000 shots on cold chamber and hot chamber die casting machines with clamping forces of up to 1250 tons. We complete the cast pieces with CNC machining centers to obtain excellent quality. If desired, we will assemble your diecast pieces into modules and assemblies after adding customised components to them in additional production phases.

For housings, coverings, fittings, or mountings, die cast components are utilized in many different industrial sectors. We provide die cast surfaces for ornamental purposes, enhanced corrosion protection, or enhanced wear resistance depending on the needs. Aluminium casting products may have the following surfaces depending on the alloy and finishing method: sandblasting, glass bead blasting, barrel finishing, brushing, polishing, phosphating, passivating, powder coating, wet painting, eloxating, copper plating, nickel plating, screen printing, or pad printing.

DIE CASTING MOLD PROCESSING CAPACITY

CAD/CAM, CATIA V5, UG, Pro-E

In-House Tooling Design & Manufacturing

Moldflow Simulating

MOULD WORKSHOP

DIESTING MOLD DESIGN PROCESS

DIE CASTING MACHINE LIST

POST PROCESSING MACHINE LIST