- Metal Injection Molding MIM Parts

- Powder Metallurgy

- Die Casting

- 3D Printing

Story With Customer

Powder Metallurgy

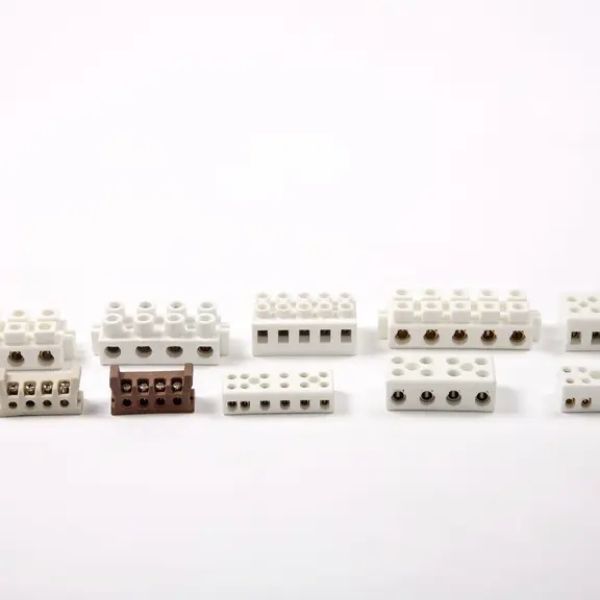

What are Powder metallurgy products?

Powder metallurgy products are sintered parts manufactured by powder metallurgy method with certain dimensional accuracy and can withstand tensile, compression, distortion and other loads or work under friction and wear conditions, also known as sintered parts.

Methods: The formed and subsequently sintered parts were pressed in a uniaxial rigid die at room temperature.

Application: Powder metallurgy parts are mainly used in the automotive industry, and have better applications in the future.

The advantages of powder metallurgy parts

- When the parts have irregular shapes, protruding or pits, and various special-shaped holes, powder metallurgy is easy to manufacture, and there is no need or only a small amount of supplementary cutting. It has obvious economy.

- When using powder metallurgy process to produce mechanical parts, the material utilization rate can reach more than 99.5%.

- Because the parts of the powder metallurgy process are produced with molds, the consistency of the outline, shape and size of the parts is very good, and there are many variables in all aspects of mechanical processing, it is difficult to maintain consistency.

- The powder metallurgy process can integrate several parts into the manufacturing process, which can save later processing and assembly costs.

- The material density of the powder structure parts is controllable, has a certain amount of connected pores, and is generally soaked with 5%-20% lubricating oil to provide a certain degree of self-lubrication, thereby improving the wear resistance.

- In powder metallurgy production, in order to facilitate the removal of parts from the die after forming, the working surface of the die has a high finish, so that the parts have an amplitude modulation finish. In addition, powder metallurgy structural parts can also be electroplating, coating, heat treatment and other subsequent treatment like mechanical parts.

Disadvantages: Due to the existence of residual pores, its ductility and impact value are lower than that of castings with the same chemical composition, thus limiting its application range.

Powder metal design guide

The powder metallurgy process can produce parts in a wide range of sizes and shapes, and the maximum size of the parts that can be produced depends on the available press capacity.

The easiest part shape to make by powder metallurgy process is the one with the same size in the pressing direction. Parts with holes in the pressing direction are generally formed with mandrel. Keys and keyways located in the pressing direction are easy to press, and shape features such as grooves, holes, cones, concave angles and threads at an Angle to the pressing direction cannot be pressed by general powder metallurgy processes. However, with a more complex structure of the mold can be formed more complex shape parts. That has added a cost.

Gears, ratchets and cams

Gears, ratchets and cams are especially suitable for production by powder metallurgy processes.

Advantages of powder metallurgy production:

① The dimensional accuracy of gear in mass production is uniform.

② Because the material organization contains a certain porosity, it helps the gear to run smoothly and can be self-lubricating.

③ Powder metallurgy gear with blind Angle can be made.

The gear and other shape parts can be integrated by powder metallurgy process.

⑤ Can produce various shapes of gear.

⑥ Simple production and low cost.

Powder metallurgy tolerances

The size fluctuation between powder metallurgy parts is mainly caused by the change of pressing pressure.

In view of the same pressing pressure, the longitudinal elastic deflection of the die punch is larger than the elastic expansion of the negative die, so the dimensional tolerance in the pressing direction is larger than that in the vertical pressing direction.

Mechanical relations:

△ die punch / △ die die = 3L/D

D represents the average radial size of the cavity of the negative model.

L represents the total length of the die punch.

How to reduce dimensional tolerances

The dimensional tolerance of the part can be improved by finishing, which is to put the sintered part in the negative die and press it with die punching, that is, to press it again in the finishing die. The main purpose of finishing is to correct the distortion caused by sintering.

Machining of powder metallurgy parts

The main purpose of using powder metallurgy parts is to achieve less cutting, no cutting processing, energy saving, material saving, reduce the production cost of parts. Powder metallurgy parts are not as easy to cut as the corresponding conventional metal parts. Due to the intermittent cutting action caused by the pores in the material structure, the tool life is short and the surface roughness of the part is poor.

Standard for determining the machinability of powder metallurgy: determine the machinability by measuring the number of holes that can be drilled. The value of 1045 steel is specified to be 100, and the machinability rating can be determined by the following formula

Machinability rating = the number of holes drilled in sintering/the number of holes drilled in 1045 steel ×100

Mn, P, S and other additives are added to the material to improve the machinability of powder metallurgy parts. The cutting properties of powder metallurgy materials can also be improved by properly selecting carbide cutting tools and the geometry of the tools.

Effect of material density on powder metallurgy parts

In the production of powder metallurgy structural parts, repressing and secondary sintering are often used to improve the material density of the parts, and the structural parts are produced according to the process route of pressing -- primary sintering -- repressing -- secondary sintering. The material density of the parts can be increased to about 95% of that of ordinary iron by re-pressing, secondary sintering and warm pressing.

Repressing is similar to finishing, the higher pressure applied during repressing is only to increase the overall density of the part, and secondary sintering refers to re-sintering after repressing. The strength and toughness of the structural parts can be improved due to the high material density of the structural parts after re-pressing and secondary sintering.

Chemical composition and mechanical properties

The powder metallurgy parts produced by the general pressing and sintering process are porous, and their mechanical properties are lower than those of dense metal materials with the same chemical composition produced by conventional methods. In order to improve the mechanical properties of powder metallurgy structural parts:

Now the raw material powder with alloying elements are: iron powder, copper powder and graphite powder mixed powder, iron powder, nickel powder, graphite powder mixed powder, iron powder, phosphorus iron powder mixed powder, diffusion alloyed powder, to alloyed steel powder and stainless steel powder.

The production processes used are: pressing - sintering, pressing - pre-sintering - repressing - sintering, warm pressing - sintering, hot pressing, hot forging and so on.

Development trend of powder metallurgy parts

The development trend of such materials is to reduce or eliminate the residual pores inside the material, and develop iron-based materials alloyed with chromium, manganese, titanium, silicon and other elements to improve the mechanical properties of the material and expand the application field.

Jiehuang is a famous powder metallurgy products company in China, Jiehuang products are sold to all countries in the world, especially to Italy, Poland, Denmark, USA, UK and other countries, please send your drawings, we will reply you immediately!