About Us

Ningbo Jiehuang Chiyang Electronic Tech Co.,Ltd. is a leading one stop metal parts solution provider in China.Our team have many years of experience in developing custom metal parts.we have powder metal manufacturing and metal injection molding parts and Die casting products(Alumimin diecasting and Znic Alloy die casting ) Our products are mainly applied to 3C (Computer, Communication, Consumer Electronics) sectors Auto parts, and industry parts. We will work with you through all phases of project development – from requirement planning, tooling design and build, to FOT and manufacturing, through to the shipping and logistics.Hoping be your First choice!

-

200+

Employees

-

20+

R&D

-

30+

QC workers

-

8+

experts

-

28000+

square meters facilities

010203040506

0102

Quality

20 years in metal injection molding technology

ISO9001-2008/ IATF 16949 Certificated factory

Japan-Imported manufacture facility

Partnership with worldwide brands in Japan, America, and Europe.

Read more

Your Best Choice

More than 85% of engineers with more than 6 years of MIM development experience.

AT least 10 projects are developed each month

Above 80% of projects can be finished as the planned timeline

BEST SOLUTION

Based on the customer’s project information, we should help partners take comprehensive. Consideration of materials, cost, post-process, quantity, and timeline to figure out the best solutions among MIM, CNC, Die casting, tamping, and others.

INQUIRY NOW

-

1

Can you sign our NDA before we provide sensitive project information?

Yes, this is a routine operation for most companies before making an inquiry. -

2

Do you provide proofing services?

We have metal 3D printing equipment and can provide sample 3D printing. -

3

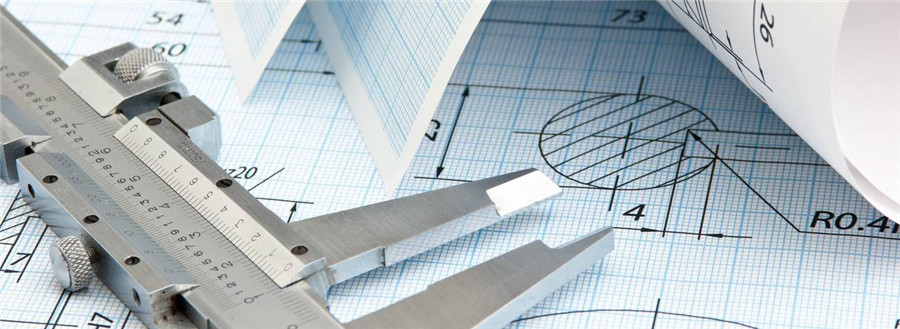

Why do I need to provide 2D (PDF) and 3D (STEP) drawings during inquiry?

3D drawings allow engineers to better understand the structure of the product, and 2D documents can provide more information, including materials, tolerances, surface treatment, etc. More detailed information is conducive to more accurate quotation by engineers. -

4

How long does it take to get a quote after sending an inquiry?

In the case of detailed inquiry drawings and information, it usually only takes 2-3 days for us to give you a detailed quotation, including product price and mold price. -

5

What preparations need to be made before confirming production?

After confirming the order, we usually take 5-7 days to prepare the DFM report of the product. After confirmation, we spend 25 days to complete the mold, and provide T1 samples to customers for testing in the following 10-15 days.If there is a problem with the test, we will re-sample it for free based on the feedback and provide a suitable sample. -

6

What is the MOQ?

MIM products MOQ 2000 PCS,CNC products MOQ 2000 PCS,Alu die casting, MOQ 2000 PCSPM product MOQ 5000 PCS -

7

JH MIM lead time?

Typically, the lead time for processing and submitting samples is 30 days. However, according to the order quantity and special requirements of customers, we can extend or shorten the delivery cycle accordingly. -

8

How to ensure quality?

1-year product warrantyWorld-class testing equipment30+QC WorkersKey sizes 100% checking before shipmentISO9001+IATF16949 -

9

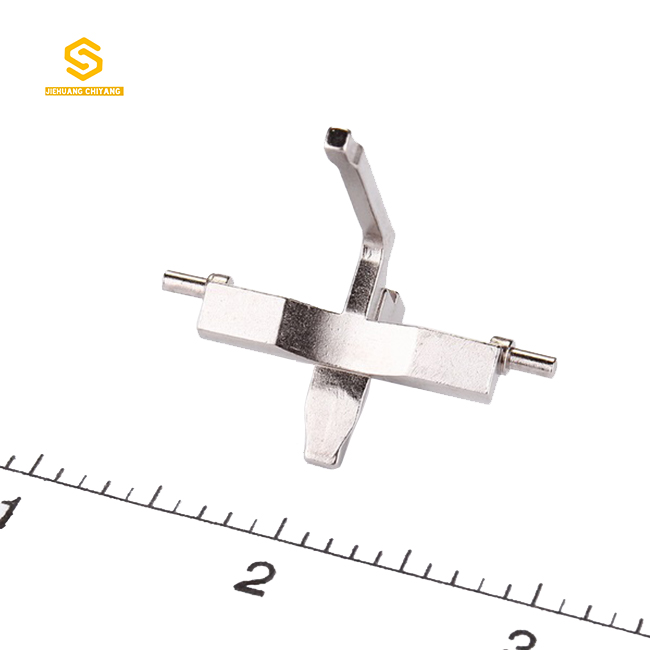

What size products is suitable for the MIM process manufacturing?

Due to the size limitations of the mold and sintering furnace, and the control of sintering shrinkage, MIM usually produces parts weight less than 100g.The largest mass-produced product made by JH MIM is 286g. However, the cost advantage of MIM for products that are too large is not great. Our engineers will recommend the most appropriate processing method based on your drawings.