PRESSURE DIE CASTING CHINA

JIEHUANG is glad to offer top-notch engineering services,low MOQ start from 1000 pcs,from producing high-end aluminum die castings and zinc die casting to assembly and finishing work. Modern equipment, procedures, and a highly qualified team support what we do. We've been committed to creating better parts, and along the road, we've assisted countless industries in discovering value and performance.

WHAT WE DO ?

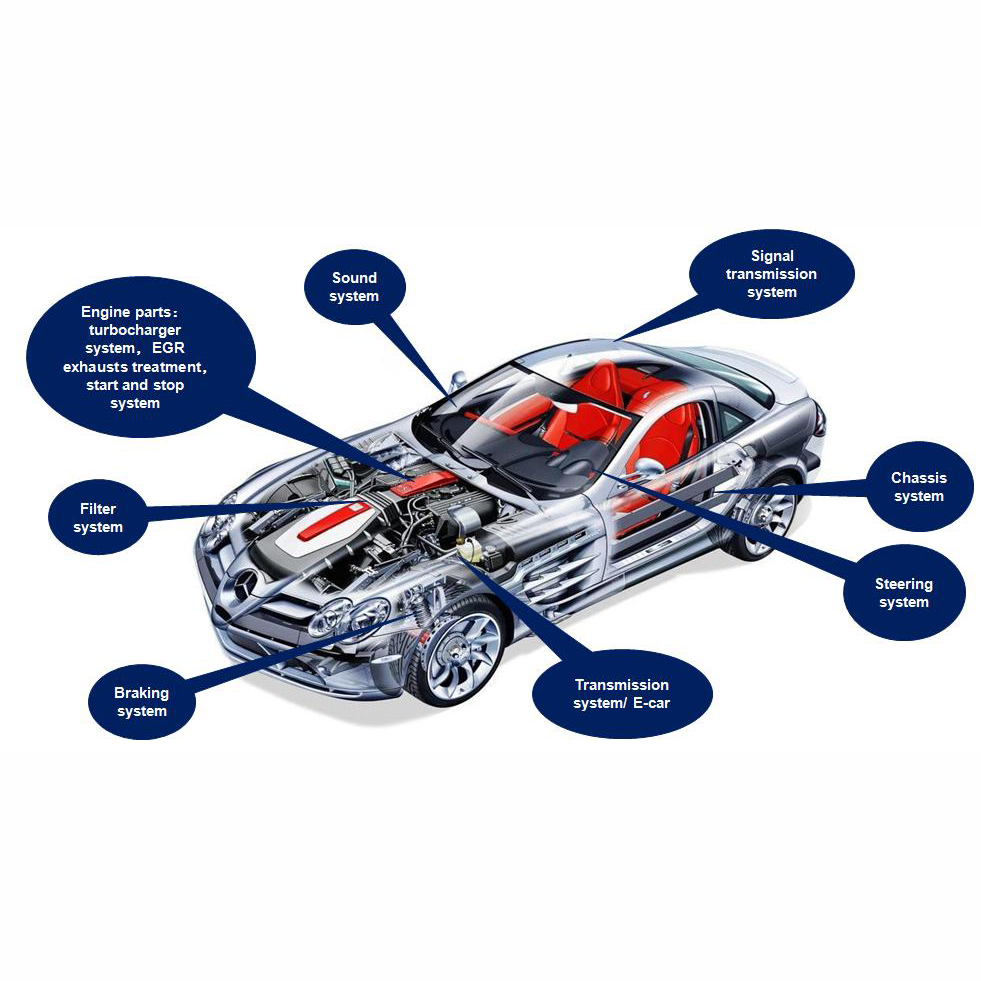

At JIEHUANG, aluminum die casting is at the core of what we do. JIEHUANG die casting connector housing has more than 15 years' worth of experience, and it has its own design teams for tools and a mold-making facility..We create and create unique parts that are made specifically for the projects of our customers. We provide customers from all industries with quality products and versatile die casting services through our highly effective methods, For example, communication equipment, new energy vehicles, the medical field, and die casting in automotive industry all frequently employ our bespoke pressure die casting parts.

Automobiles and recreational vehicles: Our team produces the components that keep businesses running every day, from the chassis to the counter mounts.

Medical equipment: Extremely precise and exact parts are required for medical equipment. That demand can be rapidly filled with die cast pieces.

Telecommunications and lighting are two businesses that depend on electrical enclosures to supply necessary tools for weatherproofing various environments. For any application, we create custom enclosures.

Firearms: High accuracy and dependable parts are required for firearms. These crucial components are routinely produced by the die casting manufacturer JIEHUANG for use by the military, industry, and law enforcement.

Industrial equipment: JIEHUANG also manufactures a variety of specialized housings, pumps, and air compressors for industrial equipment.

one-stop China factory for die casting tool design and production.

Electric Vehicles Aluminum Die casting

In order to reduce weight and improve battery life of new energy electric vehicles, there is a large demand for aluminum alloys.

The surface treatment of zinc-aluminum alloy die castings is: powder spraying, baking paint, passivation treatment, anodizing, polishing, electroplating, powder spraying, electrophoresis, sand blasting, shot blasting, etc.

WHY US

JIEHUANG is a skilled manufacturer of aluminum die casting in China, and one of its advantages is the ability to produce customized, precise zinc die casting die casting parts and aluminum casting products.

WELCOME WORK WITH US CHINA DIE CASTING,IF YOU HAVE A INQUIRY, PROVIDE THE FOLLOWING PARAMETERS.

1, Material: Aluminum and Zinc Alloy

2. Drawings: Both 2D and 3D drawings are acceptable.

3,Certificate:SGS,ROHS,IATF16949,etc

4, Delivery time: 30–45 days for the mould,20–30 days for mass manufacturing and

5, Mold:In-house tool design and production

6, Surface treatments: such nickel plating and sandblasting, etc.

7, TEST:00% inspection before delivery.

EXW, FOB, CIF, and CFR are all options.

Advantages of aluminum alloy die castings and zinc alloy die castings

1. Aluminum die castings have high dimensional accuracy and good surface quality. It has better surface roughness and less thermal cracking, and has good interchangeability.

2. The die casting process has good fluidity and can produce various difficult die castings with complex shapes, clear outlines, deep cavity and thin walls.

3. die casting products as high strength and hardness.

4. pressure die casting High material utilization rate, suitable for mass production.

5. pressure die casting products good electrical and thermal conductivity, accurate die casting size, reducing machining counter-offers and saving product costs.

Blow Customers trust us