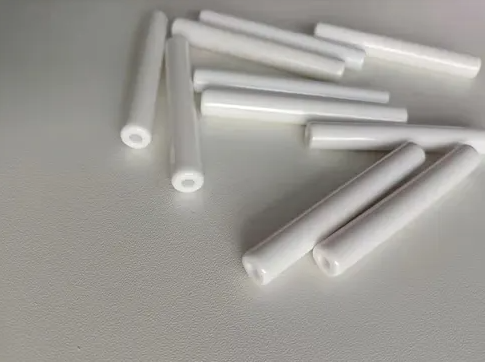

Customized ceramic injection molding watch case for wrist accessories

Ceramic injection molding

Ceramic injection molding is a cutting-edge technology that is used to create high-precision components in medium to large quantities that are created to exact client specifications. It is a crucial component of many industries. More robust, resilient, and hard than plastic molding or machined steel parts, ceramic components have a wide range of applications.

Therefore, please consider our skilled team in China JIEHUANG if you're considering ceramic material for your part requirements. If you are not familiar with the ceramic injection molding procedure, you can find out what it comprises specifically and how it might help your business.

What is injection molding of ceramics?

Custom ceramic parts are made using the injection mold technique, which is similar to that used with plastics, in a process known as ceramic injection molding (CIM). To create components that precisely match the part design specified by the customer, a pelletized mixture of alumina powder and a few binders is heated up beforehand and then pushed under intense pressure into a specially constructed mold. The part goes through a number of further procedures after being taken out of the mold, including sintering at a high temperature.

In the early part of the 20th century, ceramic injection molding (CIM) was initially applied to the manufacture of spark plug elements. The multiple technological developments in the sector that occurred over a 60-year period are what led to the present CIM.

What We Do?

Our technical team have 15+ years of experience in developing custom Metal Parts.

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!

OEM Support Offered

1. The dial, face, clasp, or case back may all bear your brand;

2. Depending on your preferences, we can create timepieces in a variety of colors;

3. As per your need, we can give RoHS & CE approvals;

4. We can adapt one of our preexisting models to create a unique design that meets your needs.

5. We'll keep you informed about our newest models and newest designs.

Our strength is that we offer all services, including production, design, and packaging.

TOP caliber, factory cost, and excellent service.

Offers include OEM and ODM.

Why Choose Us?

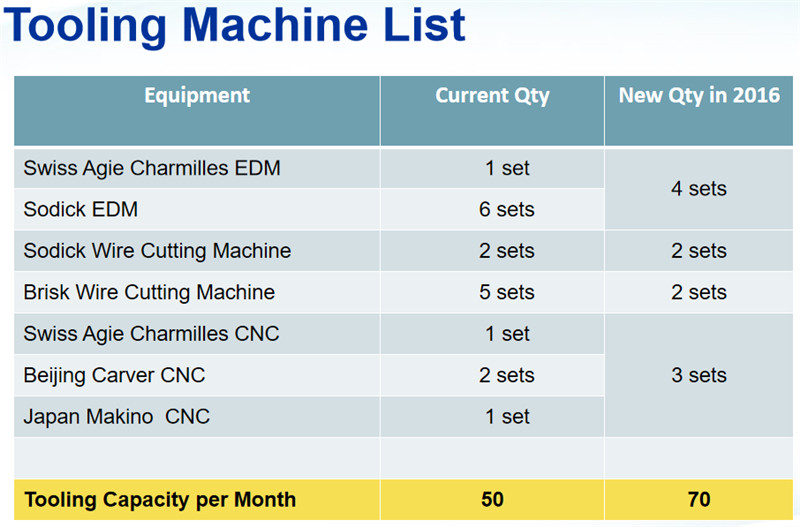

Hi-Tech Manufacturing Equipment

Our core manufacturing equipment is imported directly from Germany.

Strong R&D Strength

We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.

Quality Assurance

Strict Quality Control, Rigorous product inspection after mass production

OEM & ODM Acceptable

One-stop Metal parts supplier in China

Welcome to cooperation

If you have any enquiry for quotation, please contact us freely.

In China, Ningbo Jiehuang Chiyang Electronic Tech Co.,Ltd. is a premier one-stop shop for metal parts solutions. Our crew has years of experience creating metal parts to order. We produce powder metal, metal injection-molded components, and die-casting goods (Alumimin diecasting and Znic Alloy die casting ) Our products are mostly used in the automotive and industrial components industries as well as the 3C (Computer, Communication, Consumer Electronics) sectors. We will collaborate with you during every stage of the project's development, including requirement gathering, tool design and construction, FOT and manufacture, shipping, and logistics. wishing to be your first choice!