China Factory Customized Die Casting Parts Aluminum Zinc Brass Magnesium Alloy Die Casting Services

How do We Work with Our Client

1. For large companies with in-house engineering teams or design experts, we prefer to get a complete RFQ pack from you that includes a drawing, 3D model, quantity, and photographs;

2. You don't even need to be familiar with casting to communicate an idea to a start-up business owner or an engineering novice;

3. Within 24 hours, our sales will get back to you to confirm more information and provide an anticipated quote time;

4. Within the next one to three working days, our technical team will review your inquiry and present our offer.

5. If necessary, we may schedule a technical communication meeting between you and our engineers at any time.

|

Material

|

Aluminum alloy ADC12, ADC10, A360, A380, A356,A413,B390,EN47100,EN44100

|

|

Magnesium alloy AZ91D, AM60B

|

|

|

Zinc alloy ZA3#,ZA5#,ZA8#,Zmark3,Zmark5,ZDC3

|

|

|

Brass:HPb59-1,HPb62-1

|

|

|

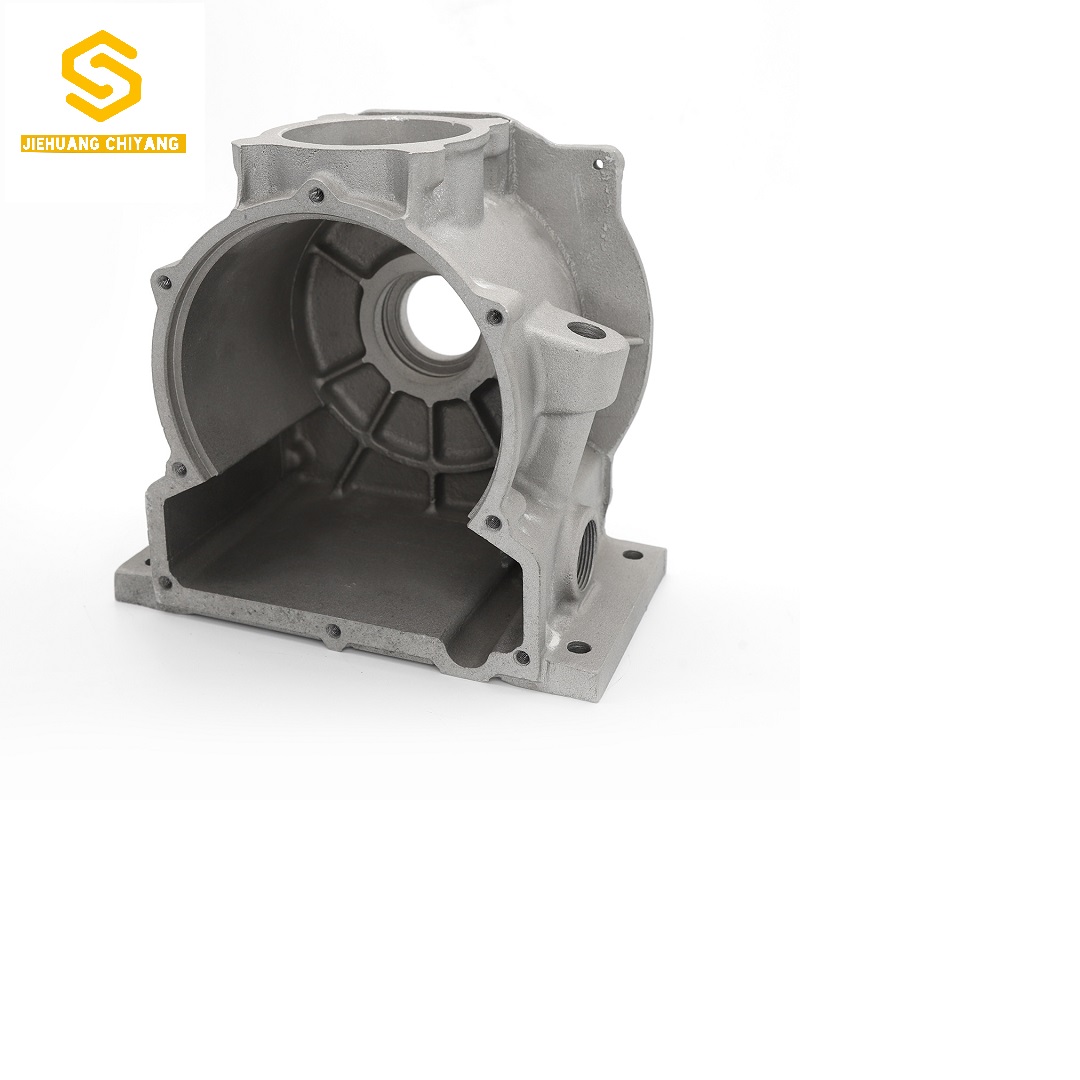

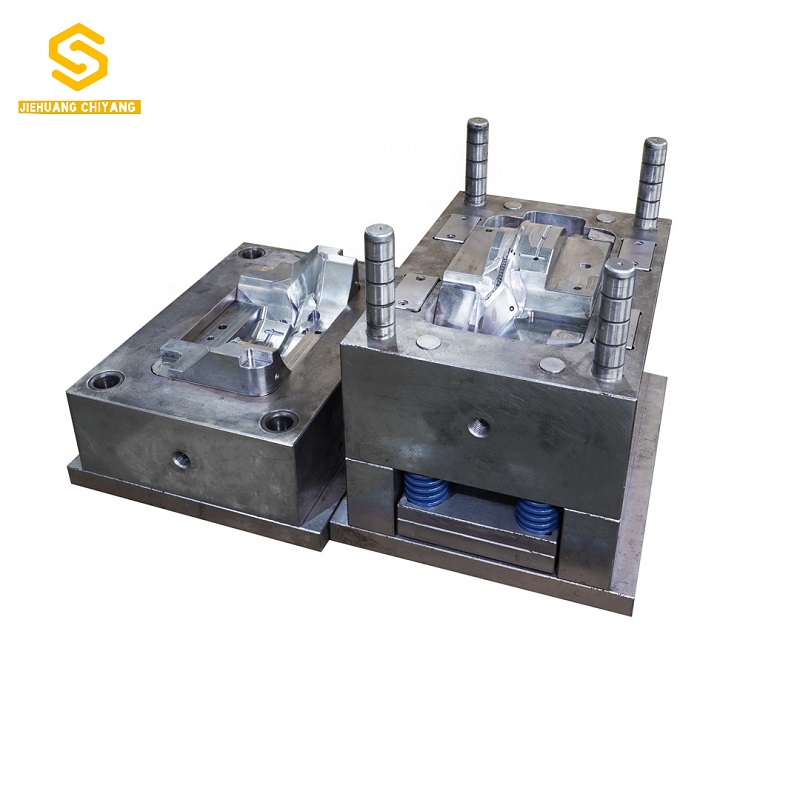

Processing Craft

|

Drawings→ mould making → die casting →rough machining → CNC machining →surface treatment →product checking→ packing →delivery

|

|

Tolerance

|

± 0.02mm

|

|

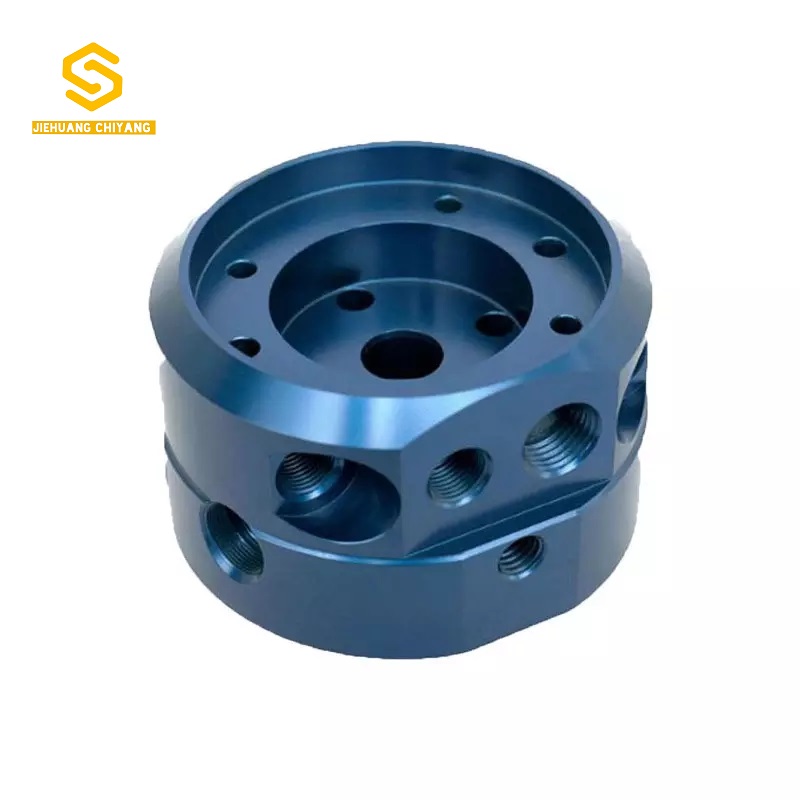

Surface Treatment

|

Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Powder coating,

Sandblasting, Passivation, Spray painting, Etc. |

|

Quality Assurance

|

ISO9001:2015 Certified, SGS Certification

|

|

Inspection

|

1.Foundry in-house: 100% inspection on critical dimension; 100% on appea rance.

|

|

2.Third Party inspection available upon requirement.

|

|

|

Mainly Testing Facility

|

Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection

|

|

Quality Guarantee

|

Two years

|

|

Features & Advantage

|

1.High machining accuracy, the flatness within 0.1mm.

|

|

2.High finish appearance, smooth surface roughness is Ra1.6 after machining.

|

|

|

3.The machining precision is high and the assembly structure is seamless.

|

|

|

4.Smooth appearance, corrosion resistance.

|

|

|

5.Pass Salt Spray Test with 144 Hours.

|

|

|

Standard

|

1.Aluminum alloy : ISO3522-84, ASTMB85-96, ASTMB597-98

|

|

2.Magnesium alloy : ISO/DIS16220-1999, ASTMB93/B93M-98,JISH2222-1991

|

|

|

3.Zinc alloy: ISO301-1981, ASTMB86-98, ASTMB240-98, ASTMB327-98

|

MOULD WORKSHOP

MOULD DESIGN PROCESS

DIE CASTING WORKSHOP MACHINES

CNC WORKSHOP

What We Do?

Our technical team have 20+ years of experience in developing custom Metal Parts.

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!