- Metal Injection Molding MIM Parts

- Powder Metallurgy

- Die Casting

- 3D Printing

Story With Customer

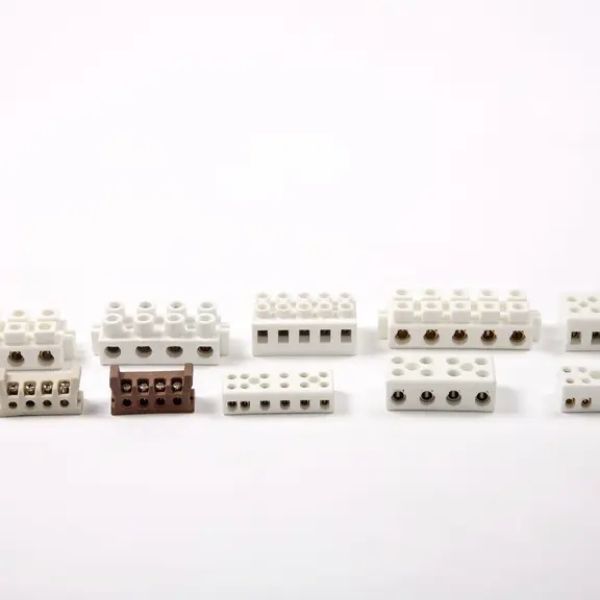

Znic Die Casting

Zinc lock components, such as the lock cylinder and core.

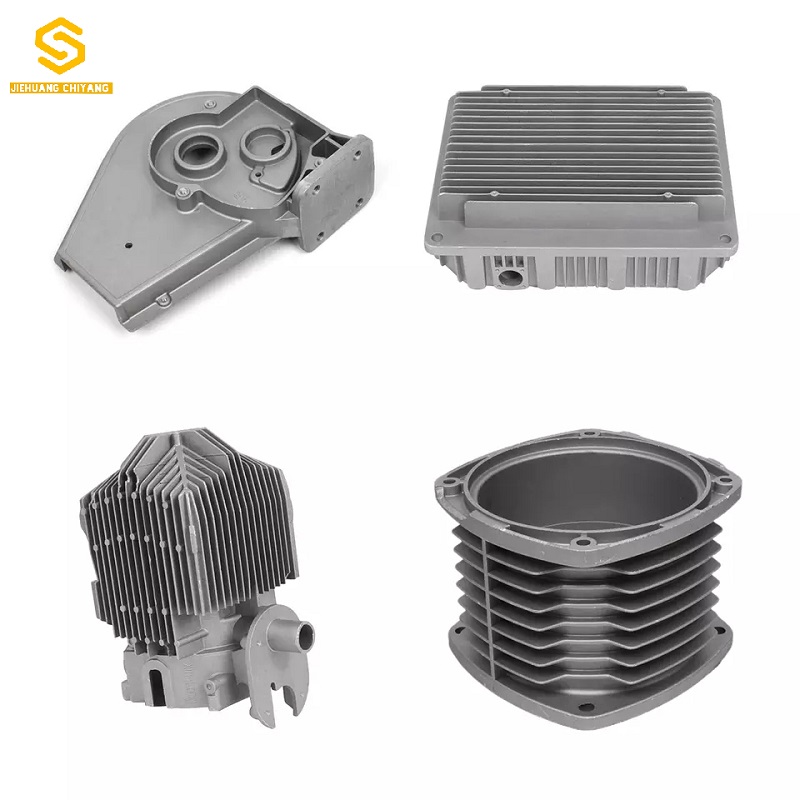

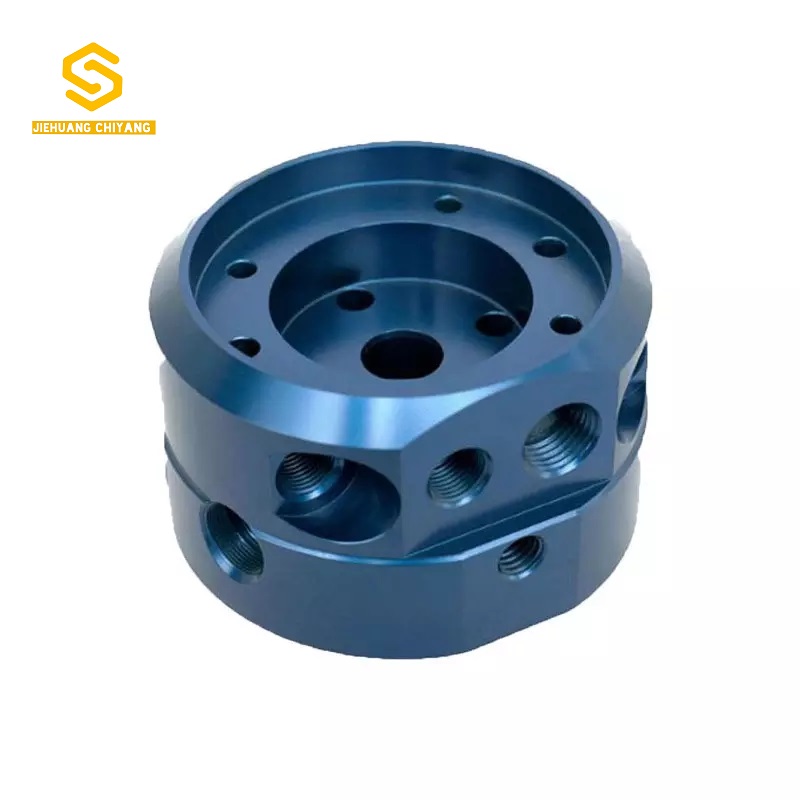

OEM zinc die cast parts for zinc lock bodies 20x20 cm maximum product size machines up to 300 tons in size designing and creating die-casting molds for zinc alloy. Die casting is a precise casting technique that forces molten metal into a metal mold with intricate shapes by applying tremendous pressure. It is a technique for precise casting. You cannot have an excellent die-casting machine and a good die-casting product. To produce a high-quality product, you must combine the die-casting machine, the die-casting technique, and the mold. Die castings made of zinc alloy have the following product characteristics:

1. The specific gravity is large, the weight is more textured, and it is stronger than plastic injection molding.

2. Good casting performance, it can die-cast precision parts with complex shapes and thin walls, and the surface of the castings is smooth.

3. Surface treatment is available: electroplating, spraying, painting.

4. It does not absorb iron during melting and die-casting, does not corrode the molding, and does not stick to the mold.

5. It has good mechanical properties and wear resistance at room temperature.

6. Low melting point, melting at 385℃, easier to form than aluminum alloy die casting.

7. Zinc alloy has a strong three-dimensional effect, and the surface will have graininess or wrinkles after die-casting, which needs to be polished. Polishing does not completely change the physical form. 8. Zinc alloy handicrafts and embossed patterns are vivid and widely used, but they require a high level of craftsmanship, and there will be a small number of indentations or burrs on the surface.

Home

Home