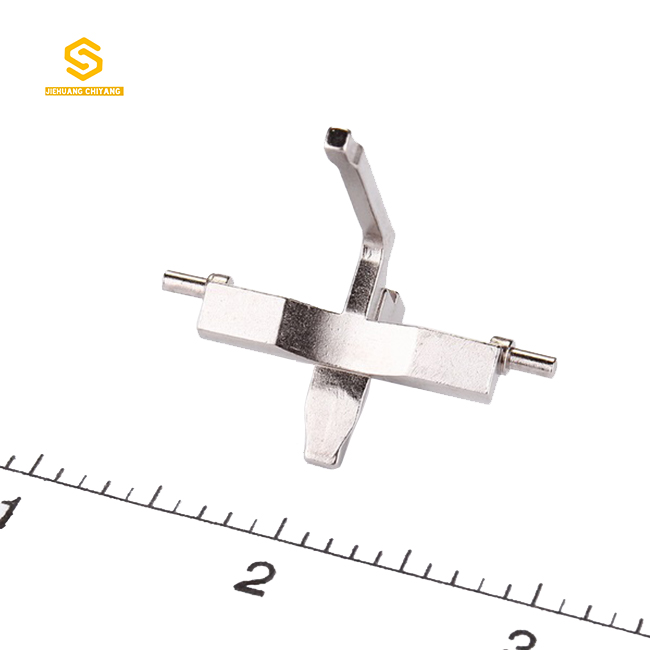

High-Quality Powder Metal Parts for Industrial Applications

Introducing our high-quality powder metal parts by Ningbo Jiehuang Chiyang Electronic Tech Co., Ltd. With years of experience and expertise in the field, we are proud to offer a wide range of powder metal components that are designed to meet the specific needs of our customers, Our powder metal parts are manufactured using advanced technology and the highest quality materials to ensure durability, precision, and reliability. From simple to complex shapes, we can provide customized solutions for various industries, including automotive, aerospace, electronics, and more, Our commitment to quality and innovation has enabled us to deliver cost-effective and efficient powder metal parts that exceed industry standards. Whether you are in need of gears, sprockets, bushings, or any other complex metal component, we have the capabilities to meet your requirements, At Ningbo Jiehuang Chiyang Electronic Tech Co., Ltd., we take pride in providing exceptional customer service and technical support to ensure satisfaction with every product. Contact us today to learn more about our powder metal parts and how we can meet your specific needs

- How Metal Powder Is Made

- Aluminium Alloy Die Casting Part

- China Metal Injection Molding and Metal Powder Moulding

- Sintered Bearing Bronze Bushings Mim

- Largest Die Casting Companies

- titanium injection molding

- metal injection molding services

- Application Of Powder Metallurgy

- Powder Metallurgy Mim Gear Parts

- Mim Supplier

Home

Home