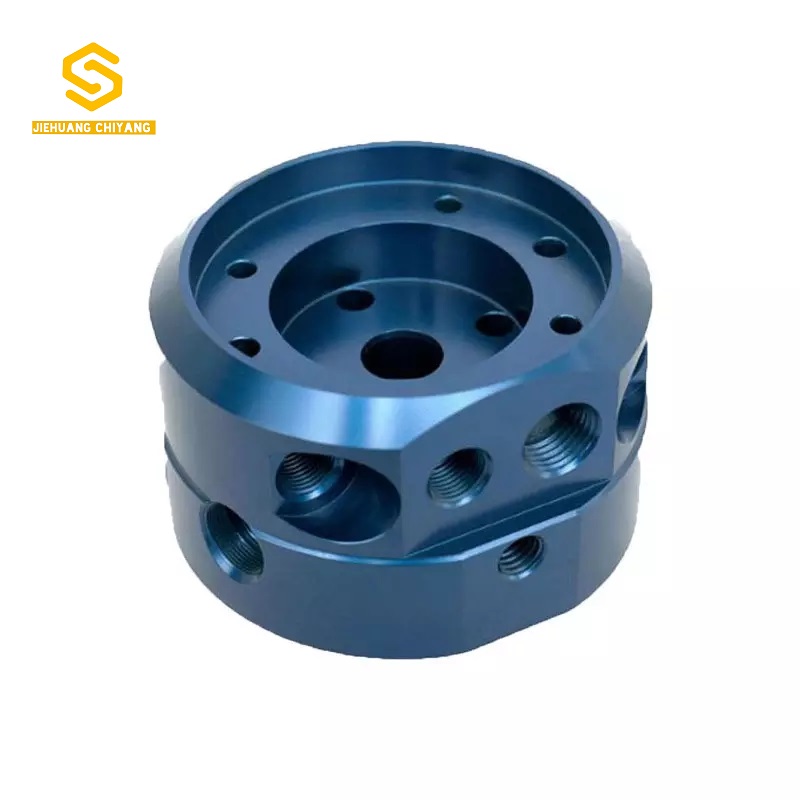

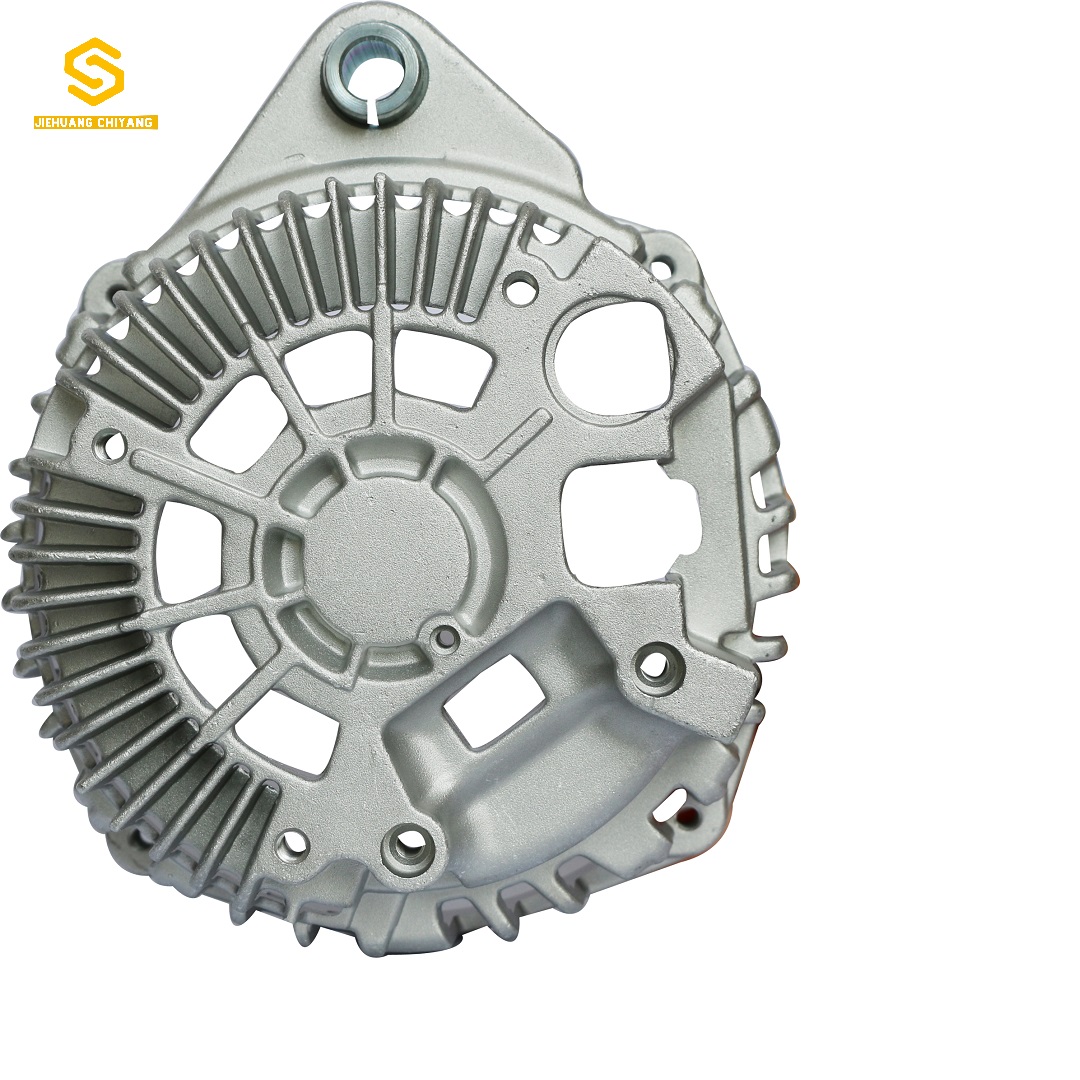

Chinese Professional Custom Industrial Electromechanical & Power Tools High Quality Iron Based Powder Metallurgy Products Made in China

Our commission is to provide our end users and clientele with best high quality and competitive portable digital merchandise for Chinese Professional Custom Industrial Electromechanical & Power Tools High Quality Iron Based Powder Metallurgy Products Made in China, The principle of our organization would be to deliver high-quality items, specialist service, and honest communication. Welcome all close friends to place trial purchase for making a long-term small business romance.

Our commission is to provide our end users and clientele with best high quality and competitive portable digital merchandise for China Powder Metallurgy and Auto Parts, We follow superior mechanism to process these items that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that permit us to provide unmatched quality of products and solutions for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

The basic processes of powder metallurgy process.

1. Preparation of raw material powder. Existing powder making methods can be broadly divided into two categories: mechanical and physicochemical methods. The mechanical method can be divided into: mechanical crushing and atomization method; physicochemical method is divided into: electrochemical corrosion method, reduction method, chemical law, reduction – chemical law, vapor deposition method, liquid phase deposition method and electrolytic method. Among them, the most widely used is the reduction method, atomization method and electrolysis method.

2. Forming the powder into a desired shape. The purpose of forming is to produce a billet of a certain shape and size, and to make it have a certain density and strength. The methods of forming are basically divided into pressurised forming and non-pressurised forming. The most commonly used method of pressurised forming is moulding.

3. Sintering of billets. Sintering is a key process in the powder metallurgy process. After forming, the pressed billet is sintered to give it the required final physical and mechanical properties. Sintering is also divided into unit system sintering and multi-system sintering. For the solid phase sintering of unitary and multiple systems, the sintering temperature is lower than the melting point of the metals and alloys used; for the liquid phase sintering of multiple systems, the sintering temperature is generally lower than the melting point of the refractory components and higher than the melting point of the fusible components. In addition to ordinary sintering, there are special sintering processes such as loose-fitting sintering, melt-impregnation method and hot pressing method.

4.Post-processing of the product. After the sintering treatment, according to the different requirements of the product, to take a variety of ways. Such as finishing, oil dipping, machining, heat treatment and electroplating. In addition, in recent years, some new processes such as rolling and forging are also used in the processing of powder metallurgical materials after sintering, achieving more desirable results.

Our Strength

Now we are HUAWEI,XIAOMI,OPPO.Xiao tiancai, HP,DELL …supplier.

It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company’s proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

Our Advantages

Service provider, a high-tech enterprise integrating R&D, production and sales.

Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .

What We Do?

Our technical team have 20+ years of experience in developing custom Metal Parts.

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!

Why Choose Us?

Welcome to cooperation

If you have any enquiry for quotation, please contact us freely.

On 2017, we sent a international bussiness dep. in Ningbo, –Ningbo Jiehuang Chiyang Electric Tech Co.,Ltd. to deal with all our international bussiness.Our group has been chosen as the preferred supplier by lots of well-known companies for its custom metal products with competitive price, stable performance and high technology.We sincerely want to be your good business partner for a long time in China. If you have any enquiry for quotation, please contact us freely. Your OEM metal parts are welcome. Our efficient and friendly sales team will always offer you very competitive quotations and a fast response to all your enquiries.

Hoping be your First choice of MIM partner!

Our commission is to provide our end users and clientele with best high quality and competitive portable digital merchandise for Chinese Professional Custom Industrial Electromechanical & Power Tools High Quality Iron Based Powder Metallurgy Products Made in China, The principle of our organization would be to deliver high-quality items, specialist service, and honest communication. Welcome all close friends to place trial purchase for making a long-term small business romance.

Chinese Professional China Powder Metallurgy and Auto Parts, We follow superior mechanism to process these items that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that permit us to provide unmatched quality of products and solutions for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.