Quality Inspection for High Quality Powder Metallurgy Pressed Copper Oil Bearing for Motor

So that you can supply you with comfort and enlarge our company, we also have inspectors in QC Workforce and guarantee you our greatest service and item for Quality Inspection for High Quality Powder Metallurgy Pressed Copper Oil Bearing for Motor, Sincerely look forward to serving you in the near future. You are sincerely welcome to visit our company to talk business face to face with each other and establish long-term co-operation with us!

So that you can supply you with comfort and enlarge our company, we also have inspectors in QC Workforce and guarantee you our greatest service and item for China Metal Injection Molding and Powder Metallurgy, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to provide you with high quality and efficient services.

First-MIM is a professional supplier of MIM parts in China. Please provide 2D, 3D drawings of the product and your requirements, we will give you feedback in 3-5 days.

Details

| Brand name | OEM & ODM |

| Product type | MIM Powder Metallurgy Military Parts |

| Material | Stainless steel 316L 304 17-4PH peptide Fe2Ni Fe4Ni Fe8Ni |

| Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

| Size | Custom |

| Tolerance | 10mm±(0.02-0.04)mm |

| Forming Method | Powder Injection Molding |

| Sintering method | Solid phase sintering |

| Sintering environment | Vacuum |

| Mold material | Stainless steel |

| Application | Military parts |

| Shape | Custom |

| OEM | Accept |

| QC system | 100% inspection before shipment |

| Payment terms | T/T at sight, Paypal, Western Union,etc. |

| Lead time | 7-15 working days |

| Supply capability | 500000 Piece Per Month |

| Packaging | PP bag / Anti-static film / anti-static plastic disc |

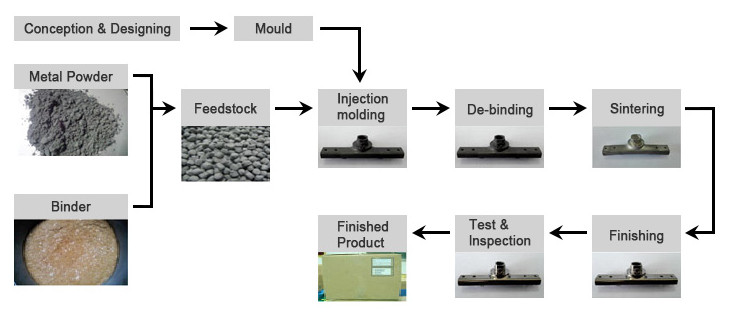

How does MIM work ?

MIM is the process which merges plastic injection molding and powdered metallurgy. It offers greater design freedom and a manufacturing capability of producing precise, complex parts in large quantities.

Contrast for MIM and Precision Casting Molding

| Property | MIM | Precision Casting Molding |

| Minimum Thickness | 0.4mm | 2mm |

| Maximum Thickness | 10mm | Unlimited |

| Minimum Diameter | 0.4mm | 2mm |

| Tolerance of Diameter 4mm | +/-0.06mm | +/-0.2mm |

| Surface Roughness | 1μm | 1μm |

Application areas for injection molding

MIM–Accessories

The Headset Accessories

Flight Instrument Equipment Parts

Smart Wearable Device Parts

Machinery And Equipment Parts

1.When can I get the price and what do I need offer?

Quotation will be provided within 24 hours after we receive full production(you need offer 2D and 3D of products)information.If the quotation is urgently,please tell us,we will speed up it.

2 What is the production cycle of MlM?

For samples,it is about 20-25 calendar days and for goods,it is about 5-7 calendar days for the first batch.

3 What material can you produce?

We can produce iron,stainless steel,ceramics,tungsten steel parts.

4.Why should I choose MlM.

The advantages of MIM is that it can produce high precision complex parts,which are difficult to be produced by traditional technologies,such as CNC or casting.

Our Strength

Now we are HUAWEI,XIAOMI,OPPO.Xiao tiancai, HP,DELL …supplier.

It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company’s proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

Our Advantages

Service provider, a high-tech enterprise integrating R&D, production and sales.

Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .

What We Do?

Our technical team have 20+ years of experience in developing custom Metal Parts.

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!

Why Choose Us?

Welcome to cooperation

If you have any enquiry for quotation, please contact us freely.

On 2017, we sent a international bussiness dep. in Ningbo, –Ningbo Jiehuang Chiyang Electric Tech Co.,Ltd. to deal with all our international bussiness.Our group has been chosen as the preferred supplier by lots of well-known companies for its custom metal products with competitive price, stable performance and high technology.We sincerely want to be your good business partner for a long time in China. If you have any enquiry for quotation, please contact us freely. Your OEM metal parts are welcome. Our efficient and friendly sales team will always offer you very competitive quotations and a fast response to all your enquiries.

Hoping be your First choice of MIM partner!

So that you can supply you with comfort and enlarge our company, we also have inspectors in QC Workforce and guarantee you our greatest service and item for Quality Inspection for High Quality Powder Metallurgy Pressed Copper Oil Bearing for Motor, Sincerely look forward to serving you in the near future. You are sincerely welcome to visit our company to talk business face to face with each other and establish long-term co-operation with us!

Quality Inspection for China Metal Injection Molding and Powder Metallurgy, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to provide you with high quality and efficient services.