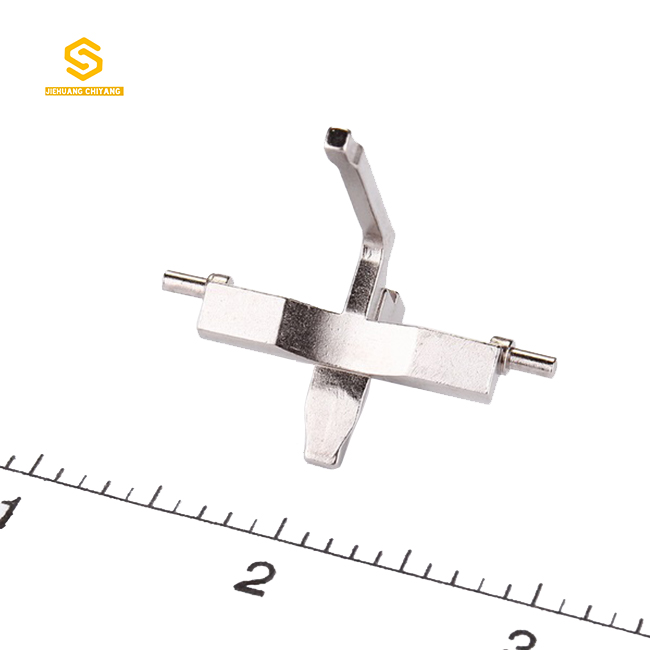

Supply OEM/ODM China Factory Hot Sale High Quality Qear Custom Structural Parts Powder Metallurgy Parts

Often customer-oriented, and it’s our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for Supply OEM/ODM China Factory Hot Sale High Quality Qear Custom Structural Parts Powder Metallurgy Parts, We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

Often customer-oriented, and it’s our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for China Powder Metallurgy Parts and Metal Powder Metallurgy Parts, With the effort to keep pace with world’s trend, we will always endeavor to meet customers’ demands. If you want develop any other new products and solutions, we can customize them to suit your needs. If you feel curiosity in any of our items or want develop new merchandise, be sure to feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

Video

Powder metallurgy?

Powder metallurgy injection molding was born in California, USA in 1973, referred to as MIM. It is a new type of powder metallurgy molding technology invented by combining plastic injection molding technology with the field of powder metallurgy.Powder metallurgy is close to the injection molding process with powder metallurgy technology, first the solid powder and organic binder mixing together, through 150 degrees high temperature heating plasticizing, injection mold cavity with injection molding equipment, again is solidified, then use the method of thermal decomposition of binder removal from the billet, the last as powder metallurgy, precision by sintering parts.

Powder metallurgy compaction molding is to use powder to fill the mold by gravity, through the machine pressure extrusion molding.In practical industrial applications is the most widely used one, cold closed steel die pressing, cold isostatic pressure, hot isostatic pressure, temperature pressure are pressing molding.However, due to the only up and down two-way pressing, some complex structural parts can not be produced, or can only be made into blank. The use of powder metal technology bypasses the need to produce the resulting products by metal removal processes, thereby reducing manufacturing costs.

As a leading powdered component manufacturer, we provides a wide variety of powdered and sintered metal gears for several applications in multiple industries. The manufacturing of sintered metal gears can present many challenges for conventional manufacturers. Gear geometries are inherently complex, often requiring time-consuming secondary machining processes – adding cost to the bottom lime. It is in this realm where powder metallurgy excels.

Through the use of precision tooling, high tonnage compaction pressure, and sintering, gears may be manufactured with the powdered metal (PM) method, to near-net-shape or even net-shape, requiring little or no machining, and at cycle times considerably faster than machining.

Benefits of Using PM in Gear Manufacturing

Utilizing PM for gear manufacturing provides many benefits including tight tolerances, quiet running PM gears, and the capacity for higher volumes. A key benefit of using powdered metal for gear manufacturing is the cost-effectiveness. The ability to produce multilevel gears combined with internal configurations and tight tolerance components eliminate or reduce the need for additional operations. All together results in time and money saved for your application.

With little to no waste, powdered metal is a green process due to its low energy usage and minimal scrap, making it more economical than standard machining or casting. Material selection for powdered metal gears allows for optimization of the component’s performance for its intended application with little variation in the manufacturing process.

Our Strength

Now we are HUAWEI,XIAOMI,OPPO.Xiao tiancai, HP,DELL …supplier.

It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company’s proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

Our Advantages

Service provider, a high-tech enterprise integrating R&D, production and sales.

Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .

What We Do?

Our technical team have 20+ years of experience in developing custom Metal Parts.

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!

Why Choose Us?

Welcome to cooperation

If you have any enquiry for quotation, please contact us freely.

On 2017, we sent a international bussiness dep. in Ningbo, –Ningbo Jiehuang Chiyang Electric Tech Co.,Ltd. to deal with all our international bussiness.Our group has been chosen as the preferred supplier by lots of well-known companies for its custom metal products with competitive price, stable performance and high technology.We sincerely want to be your good business partner for a long time in China. If you have any enquiry for quotation, please contact us freely. Your OEM metal parts are welcome. Our efficient and friendly sales team will always offer you very competitive quotations and a fast response to all your enquiries.

Hoping be your First choice of MIM partner!

Often customer-oriented, and it’s our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for Supply OEM/ODM China Factory Hot Sale High Quality Qear Custom Structural Parts Powder Metallurgy Parts, We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

Supply OEM/ODM China Powder Metallurgy Parts and Metal Powder Metallurgy Parts, With the effort to keep pace with world’s trend, we will always endeavor to meet customers’ demands. If you want develop any other new products and solutions, we can customize them to suit your needs. If you feel curiosity in any of our items or want develop new merchandise, be sure to feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.