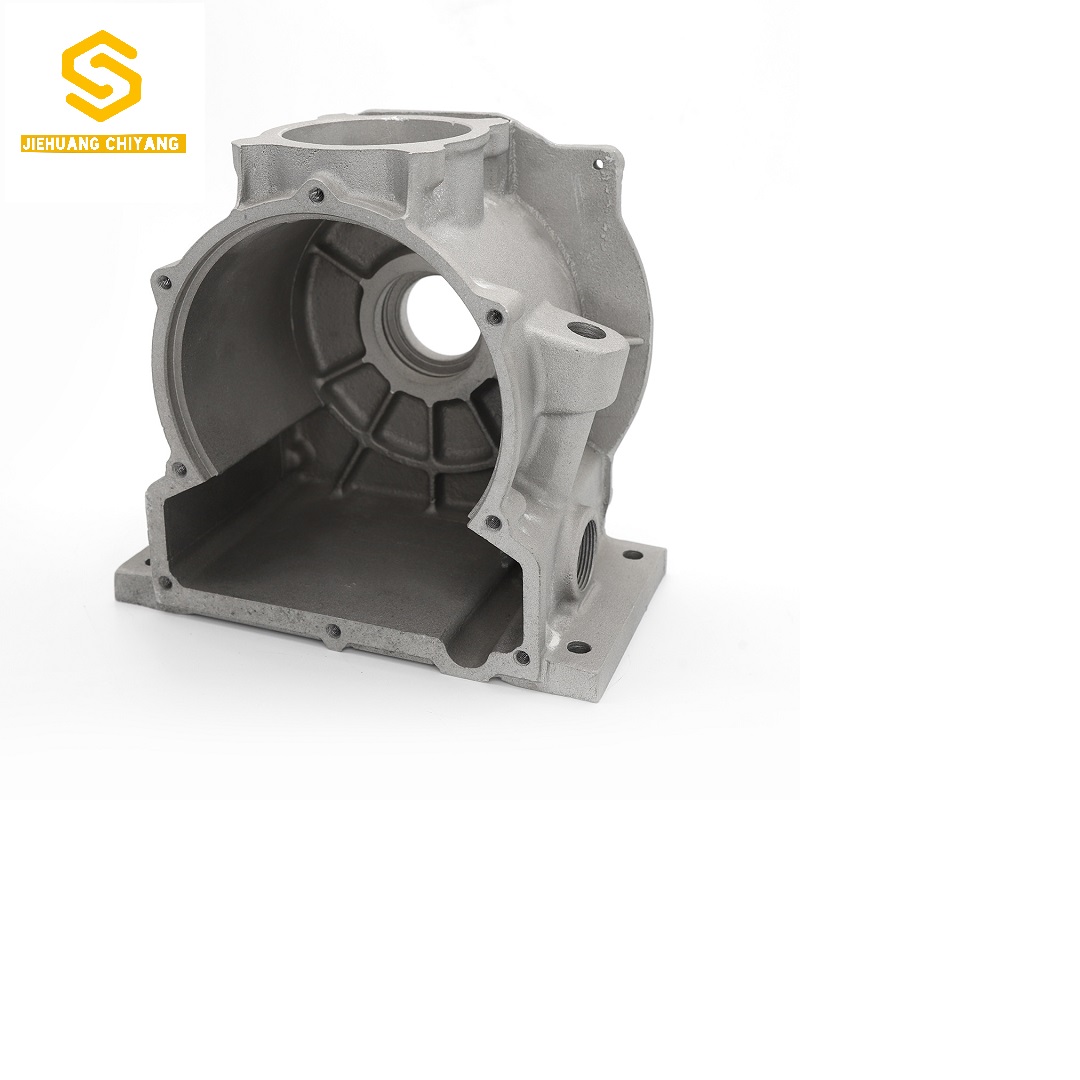

Custom Made Precision High Pressure Die Casting Aluminum Alloy Parts

|

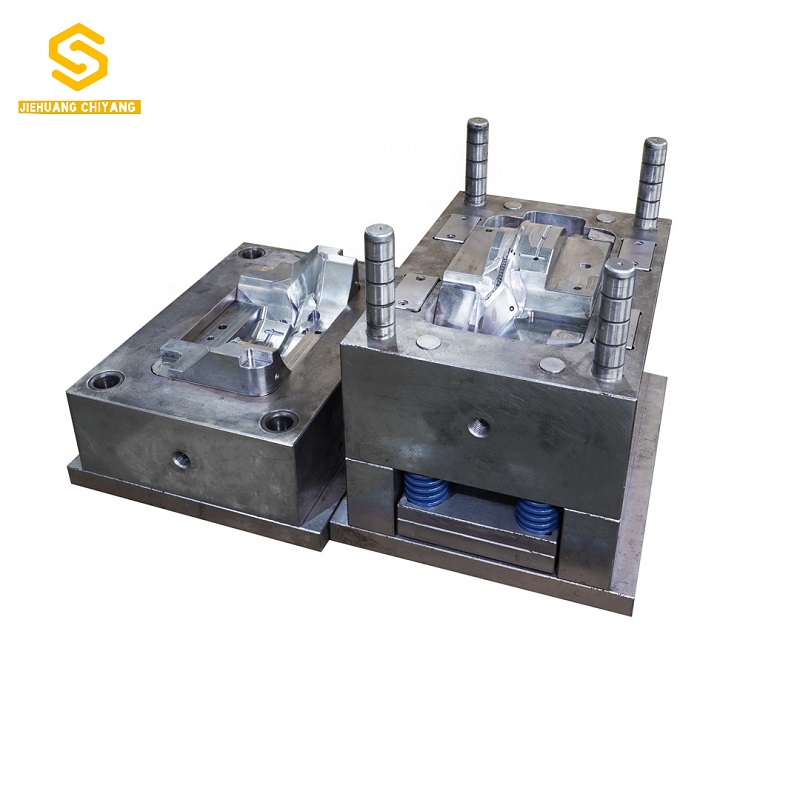

Mold Material

|

SKD61, H13

|

|

Cavity

|

Single or multiple

|

|

Mold Life Time

|

50K times

|

|

Product Material

|

1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24

2) Zinc alloy 3#, 5#, 8# |

|

Surface Treatment

|

1) Polish, powder coating, lacquer coating, e-coating, sand blast, shot blast, anodine

2) Polish + zinc plating/chrome plating/pearl chrome plating/nickel plating/copper plating |

|

Size

|

1) According to customers' drawings

2) According to customers' samples |

|

Drawing Format

|

step, dwg, igs, pdf

|

|

Certificates

|

ISO 9001:2015 & IATF 16949

|

|

Payment Term

|

T/T, L/C, Trade Assurance

|

About Us

JieHuang is specialized in pressure die casting process and aluminum/zinc metal castings production for more than 15 years, we are capable to provide complex OEM die casting parts for your specific applications and purposes. A thorough understanding of die casting techniques enables us to create cost-effective die casting products with the best performance and exact dimensions to meet your request, premium quality and competitive prices will make your stand out in local market. We’ll apply advanced machinery and systems to alleviate risk during the process. Lightweight yet strong aluminum or different zinc materials are available for selection, such as A360, A380, ADC2, etc. Several parts can be cast into a single unit, which simplifies the supply chain. DiecastingMould provides one-stop service for the OEM clients, our custom die casting parts market including door locks, automotive, heavy equipment, lightning, electrical cable clamps, vehicle, and more industries and fields. Whether you require a new product design or OEM die castings of finished design, welcome to get in touch with us, a free quote will be sent back within 24 hours. Mold design and mold making for OEM parts, as well as surface finishing services, are offered for your requirements.

OUR FACTORY

DIE CASTING PARTS

Production Process

Tolerance: +-0.05mm

Material available :Stainlesssteel,aluminium,brass,

Process:CNC machining(turning, milling, drilling)

brushing,powder coating,electroplating,zinc plating,silk-screen

PDF/DWG/IGS/STP

Description of application effect

3.Competitive Price

4.Large Quantity Production Capacity

5.Short Delivery Time

6.RoHS Compliant

7.Optional Materials:Aluminum,Brass,Stainless Steel etc

8.Specification Is Customized

9.LOGO Can Be Customized

DIE CASTING PROCESS&PACKING

Our Advantages

Service provider, a high-tech enterprise integrating R&D, production and sales.

Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .

1000+

Workers

15+

Production lines

75 Million

Annual output capacity

30+

Research results

Welcome to cooperation

If you have any enquiry for quotation, please contact us freely.

On 2017, we sent a international bussiness dep. in Ningbo, –Ningbo Jiehuang Chiyang Electric Tech Co.,Ltd. to deal with all our international bussiness.Our group has been chosen as the preferred supplier by lots of well-known companies for its custom metal products with competitive price, stable performance and high technology.We sincerely want to be your good business partner for a long time in China. If you have any enquiry for quotation, please contact us freely. Your OEM metal parts are welcome. Our efficient and friendly sales team will always offer you very competitive quotations and a fast response to all your enquiries.