- Nā ʻāpana MIM hoʻoheheʻe metala

- ʻO ka pauka Metallurgy

- Hoolei Make

- Paʻi 3D

Moʻolelo Me ka mea kūʻai aku

Hoʻoheheʻe ʻia me ka Titanium Metal Injection Molding (TiMIM)

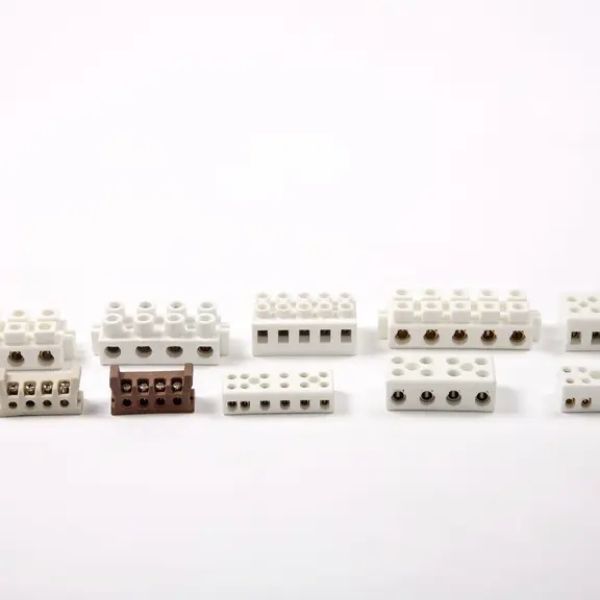

ʻO nā kila kila, nā mea hoʻohui, a me nā seramika kekahi o nā mea i loko o ka waihona MIM MoldingHoʻoheheʻe ʻia me ka Titanium Metal Injection Molding (TiMIM)hiki ke kalai.

No ka hana ʻana i kahi meaʻai e hiki ke hana ʻia e ka mīkini hoʻoheheʻe injection, pono ʻo TiMIM i ka hui ʻana i ka metala Titanium pauka me kahi mea paʻa. E kū'ē i nā ʻāpana metala Titanium maʻamau, ʻo ka hoʻoheheʻe ʻia ʻana metala e hiki ai i nā ʻāpana Titanium paʻakikī ke hoʻoheheʻe pololei ʻia i ka hana hoʻokahi a me ka leo kiʻekiʻe.

ʻO nā ʻoki lalo a me ka mānoanoa pā like ʻole a hiki i ka 0.125′′ a i ʻole 3mm nā hiʻohiʻona i hiki ke loaʻa maʻāpana TiMIM . Eia hou, hiki ke hoʻopau ʻia nā ʻāpana TiMIMmīkini ʻiainā pono a lawe i nā ʻano lapaʻau like ʻole, e like me ka anodizing a me ka electropolishing.

ʻO ka Titanium alloy kahi metala koʻikoʻi i hoʻomohala ʻia i ka waena o ke kenekulia 20, no ka haʻahaʻa haʻahaʻa, kiʻekiʻe ka ikaika kikoʻī, ke kūpaʻa maikaʻi ʻana, ke kūpaʻa wela kiʻekiʻe, ʻaʻohe magnetic, ka hana kuʻi ʻana maikaʻi a me nā waiwai maikaʻi ʻē aʻe, hoʻohana nui ʻia i ka aerospace, automotive. , Bioengineering (kūpono maikaʻi), nā wati, nā waiwai haʻuki, ka mālama ʻana i ke kaiapuni a me nā ʻano ʻē aʻe, akā maikaʻi ʻole ka hana ʻana o ka titanium a me ka titanium alloy machining, ʻo nā kumukūʻai kiʻekiʻe e kaupalena i kāna noi ʻoihana, ʻoi aku ma nā ʻāpana paʻakikī.

ʻenehana PIM hoʻoheheʻe pauka ʻO ia ka ʻenehana hoʻomohala wikiwiki loa i ka metallurgy pauka, a ua manaʻo ʻia ʻo ia ka ʻenehana hoʻomākaukau ʻenehana wela loa. ʻO ka ʻenehana ka hui pū ʻana o ka ʻenehana hoʻoheheʻe ʻana i ka pauka a me ka ʻenehana hoʻoheheʻe ʻana i ka plastic, ʻaʻole wale ka maikaʻi o ke kaʻina hana metallurgy maʻamau i ka liʻiliʻi o ke kaʻina hana, ʻaʻohe ʻoki a i ʻole ka ʻoki ʻana, nā pono waiwai kiʻekiʻe, a lanakila i ke kaʻina hana metallurgy maʻamau o nā mea haʻahaʻa. mānoanoa, mea like ole, haʻahaʻa mechanical waiwai, ʻaʻole maʻalahi e hana i ka pā lahilahi, paʻakikī structural mim mea. ʻOi aku ka maikaʻi ma ka hoʻomākaukau ʻana i nā huahana hoʻomaʻemaʻe kokoke me ka geometry paʻakikī, ka ʻano like ʻole a me ka hana kiʻekiʻe. Hiki ke hoʻokō ʻia ka geometry, nā waiwai mechanical a me ka pololei o ka huahana o ka titanium alloy powder injection molding process i hiki ʻole ke loaʻa i ka hana kuʻuna. Eia nō naʻe, ʻoi aku ka hana kiʻekiʻe o ka metala titanium a ua maʻalahi ke pane me ke kalapona, oxygen a me ka nitrogen e hoʻohua ai i ka TiC, TiO2, TiN a me nā mea ʻē aʻe, e paʻakikī ai ka hoʻomaikaʻi ʻana i ka sintering density a me nā waiwai mechanical.

Ma keʻano laulā, nā mea mim ʻaʻole e hana ma hope o ka mālama ʻana, a hoʻohana pinepine ʻia ka sintering e like me ke kaʻina hana hope loaKaʻina MIM , nona ka hopena o ka densification a me nā ʻano kemika like ʻole o nā mea alloying. No ka laʻana, i ka wā i hoʻopaʻa ʻia ai ʻo Obasi i nā laʻana Ti-6AI-4V, ʻo ka mahana o ka sintering he 1520-1680 degere Celsius.

I kēia manawa, hoʻohana nui ʻia ka titanium alloy injection molding i ka aerospace, warship, automobile, chemical and petrochemical fields, a me ka titanium alloy injection molding he ākea noi. Ua hoʻohana ʻo ʻAmelika Hui Pū ʻIa i kahi helu nui o ka titanium alloy structural ʻāpana i ke kahua aerospace. Eia kekahi laʻana,ʻo ka titanium alloy i hoʻohanaʻia ma F-22, ka hā o ka hanauna jet fighter o ʻAmelika Hui Pū ʻIa, he 38.8% o ka hale mokulele; ʻO ka hoʻohana ʻana i ka titanium o Rah-66, ka pū, he 12.7%; ʻO ka hoʻohana ʻana i ka titanium o TF31, ka aeroengine, a me ka hoʻohana ʻana i ka titanium o Apollo spacecraft hiki i 1180KG. Ma nā ʻōlelo o ka hiki, e hoʻohana nui ʻia ka titanium alloy i ka ʻoihana kīwila, ʻoi aku ka nui o nā ʻāpana automotive, nā ʻāpana lāʻau lapaʻau, nā ʻāpana graft biological.

Hoʻohana ʻia ʻo Titanium alloy i loko o nā valve engine, nā koʻokoʻo pili, nā crankshafts a me nā pūnāwai, ʻaʻole hiki ke hoʻemi wale i ke kaumaha o ke kaʻa, hoʻonui i ke ola o ke kaʻa, akā hoʻomaikaʻi pū i ka wikiwiki. No ke kahua kīwila, ʻo ke kumu kūʻai o ka titanium alloy ka mea e noʻonoʻo mua ai, ke kumukūʻai hana, nā ʻāpana hoʻokele titanium alloy kiʻekiʻe o ke ala:

1. E aʻo i nā'āpana titanium kūpono no nā koi kūikawā o TiMIM

2. E hoʻomohala i ka ʻenehana hana pauka haʻahaʻa haʻahaʻa hou no nā mea maka Ti-MIM

3. E hoʻonui i nā ʻāpana kaʻina hana Ti-MIM e mālama i ka maikaʻi o ka huahana

4. Hoʻomohala i ka ʻōnaehana hoʻopaʻa Ti-MIM ʻakaʻaka hou

5. Hoʻomohala i nā kūlana Ti-MIM no nā kaʻa, nā moku a me nā māla ʻē aʻe, a hoʻolaha i ka hoʻohana nui ʻana o ka titanium a me ka titanium alloy powder injection molding

ʻO nā mīkini hoʻoheheʻe uila o kēia wā, nā kapuahi hoʻopaʻa mau a me ka hui ʻana, nā ʻōnaehana debinding solvent, 5-axis CNC machining and grind centers, ceramic kilns, coining, laser etching/engraving, a me nā labs inspection e hana ʻia e JH MIM firm. Hāʻawi pū ʻia nā lawelawe hoʻohui waiwai piha e JH MIM, me ka prototyping wikiwiki, ka plating, ka welding laser, ka mālama wela, ka hoʻopau ʻana a me ka polishing, ka hui ʻana, ka ʻeke hope loa, a me nā mea hou aku. Ma ke ʻano he kumu waiwai nui o JH MIM, hāʻawi ʻia ka hoʻolālā no ka hana hana kōkua me ka uku ʻole. Mālama ka ʻoihana i ka hoʻolālā ʻana a me ke kūkulu ʻana i nā lua hoʻokahi a me ka nui-cavity, ka holo wela, a me ka wehe ʻana i nā pahu i nā hale kūʻai mea hana hale kokoke.

Home

Home